Stereolithography (SLA) 3D Printing Service

Table of Contents

Stereolithography (SLA) Tolerances Overview

| Feature | Standard Resolution | High Resolution |

|---|---|---|

| Build Envelope | 29” x 25” x 21” | 10” x 10” x 10” |

| Layer Height | 0.004″ | 0.002″ |

| XY Plane Tolerance | +/- 0.005” for the first inch, with an additional +/- 0.002” per inch beyond | +/- 0.005” for the first inch, with an additional +/- 0.002” per inch beyond |

| Z Plane Tolerance | +/- 0.010” for the first inch, with an additional +/- 0.002” per inch beyond | +/- 0.010” for the first inch, with an additional +/- 0.002” per inch beyond |

| Minimum Linear Feature Size | Features under 0.030” may be at risk; features under 0.020” likely won’t build | Features under 0.020” may be at risk; features under 0.010” likely won’t build |

| Minimum Radial Feature Size | 0.035″ | 0.030″ |

Note: These tolerances are standard for SLA processes and can vary due to stress during the build, support structures, and other design considerations. For more precise tolerances, a manual quote review might be necessary after successful prototype completion. General tolerances apply before any secondary finishing or post-processing unless specified otherwise.

Modo Rapid offers seamless access to premium 3D printing services, utilizing cutting-edge additive manufacturing technologies.

Choose from over 40 materials and 11 finishing options to perfectly match the requirements of any project.

SLA Materials and Their Properties

Modo Rapid offers a wide selection of SLA materials designed for specific applications. Here’s an overview of available materials and their key characteristics:

| Material Name | Description | Flexural Strength (MPa/KSI) | Elongation at Break (%) | [email protected] MPa (°C) | Data Sheets |

|---|---|---|---|---|---|

| Somos PerFORM* | White, Ceramic-filled | 146 MPa/KSI | 1% | 268 °C | |

| Accura Bluestone* | Blue, Ceramic-filled | 154 MPa/KSI | 2% | 284 °C | |

| Somos ProtoTherm 12120* | Translucent Red, PC-like | 109 MPa/KSI | 4% | 126 °C | |

| Accura 60 | Clear/Translucent, PC-like | 101 MPa/KSI | 13% | 55 °C | |

| Somos WaterClear Ultra 10122 | Clear/Translucent, PC-like | 84 MPa/KSI | 7% | 47 °C | |

| Accura Xtreme White 200 | White, ABS-like | 79 MPa/KSI | 20% | 47 °C | |

| Accura ABS Black (SL 7820) | Black (painted), ABS-like | 78 MPa/KSI | 13% | 51 °C | |

| Somos Taurus | Dark Gray, ABS-like | 74 MPa/KSI | 24% | 62 °C | |

| Somos NeXt | White, PP-like | 71 MPa/KSI | 10% | 57 °C | |

| Accura Xtreme Grey | Grey, ABS-like | 71 MPa/KSI | 22% | 62 °C | |

| Somos EvoLVe 128 | White, ABS-like | 70 MPa/KSI | 11% | 52 °C | |

| Somos WaterShed XC 11122 | Clear/Translucent, ABS-like | 69 MPa/KSI | 15% | 50 °C | |

| Accura ClearVue | Clear/Translucent, PC-like | 67 MPa/KSI | 7% | 46 °C | |

| Accura 25 | White, PP-like | 58 MPa/KSI | 20% | 63 °C |

Modo Rapid offers these materials for various industrial and commercial applications, providing flexibility in design and production.

Capabilities of SLA 3D Printers

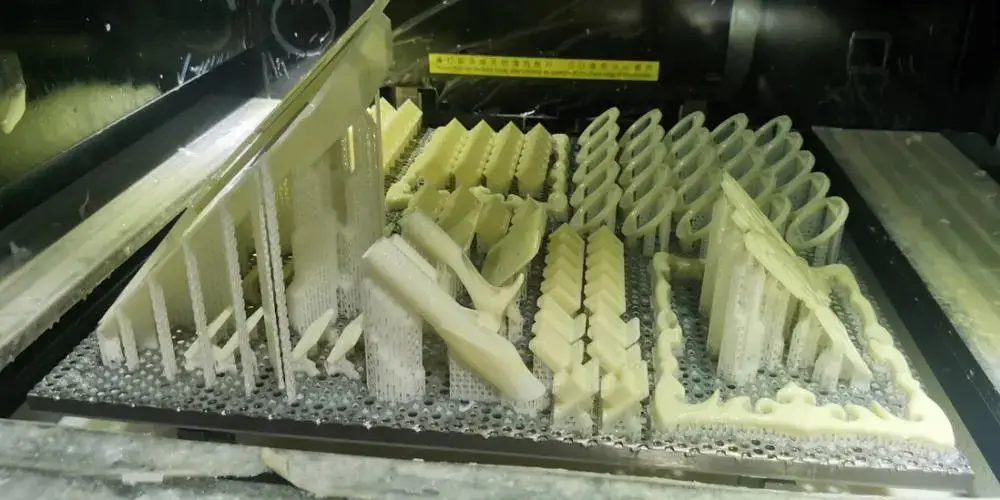

SLA 3D printing is divided into two main categories: desktop SLA for prototyping and industrial SLA. Here are the key features of each technology.

| Maximum Build Volume | Typical Lead Time | Dimensional Precision | Layer Thickness | Smallest Feature Size | |

|---|---|---|---|---|---|

| Desktop SLA for Prototyping | 145 × 145 × 175 mm (5.7 in x 5.7 in x 6.8 in) | From 3 business days | ± 0.3% with a minimum of ± 0.3 mm (± 0.012″) | 50-100 μm | 0.2 mm |

| Industrial SLA | 500 x 500 x 500 mm (19.68 in x 19.68 in x 19.68 in) | From 3 business days | ± 0.2% with a minimum of ± 0.13 mm (± 0.005″) | 50-100 μm | 0.2 mm |

Advanced 3D Printing Solutions for Engineering with SLA

Access high-precision printed components at every stage of your product development.

Compare SLA Resins for Optimal Performance

Explore resin properties and filter by application during your setup process with detailed resin profiles.

Optimize Print Resolution

Adjust layer thickness in the settings menu to achieve the perfect balance between detail and production time for SLA parts.

Enhance Surface Finish Quality

Include optional post-processing configurations by uploading your drawing with marked areas for specific finishing requirements.

SLA Post-Processing

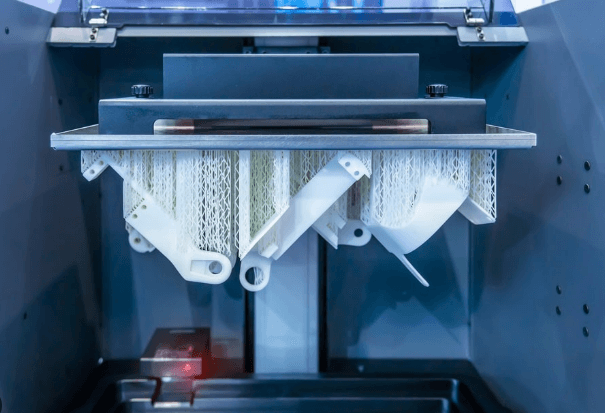

At Modo Rapid, all support structures are carefully removed, and any remaining support marks are sanded down to achieve a smooth finish. For clear resin parts, we apply a polishing oil to enhance clarity. Our Formlabs materials are cured using a Form Cure machine, following the official Formlabs “Recommended Cure” settings to ensure optimal results.

Comparison of 3D Printing Technologies

| Technology | Materials | Price | Dimensional Accuracy | Strengths | Build Volume | Layer Thickness | Min. Feature Size |

|---|---|---|---|---|---|---|---|

| FDM | 5 | $ | ± 0.5% with a lower limit of ± 0.5 mm | Low cost, wide range of materials | 500 x 500 x 500 mm (19.68″ x 19.68″ x 19.68″) | 100-300μm | 2.0 mm (0.0787”) |

| Industrial FDM | 6 | $$$$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012″) | High repeatability, engineering-grade materials | 406 x 355 x 406 mm (15.98” x 13.97” x 15.98″) | 100-330μm | 2.0 mm (0.0787”) |

| Prototyping SLA | 8 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012″) | Smooth surface finish, fine detail resolution | 145 × 145 × 175 mm (5.7″ x 5.7″ x 6.8″) | 50-100μm | 0.2 mm (0.00787”) |

| Industrial SLA | 3 | $$$ | ± 0.2% with a lower limit of ± 0.13 mm (± 0.005″) | Smooth surface finish, large build area | 500 x 500 x 500 mm (19.68″ x 19.68″ x 19.68″) | 50-100μm | 0.2 mm (0.00787”) |

| SLS | 2 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012”) | Design flexibility, no supports required | 395 x 500 x 395 mm (15.53″ x 19.68″ x 15.53″) | 100μm | 0.5 mm (0.0196”) |

| MJF | 2 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (0.012”) | Design flexibility, no supports required | 380 x 285 x 380 mm (14.9” x 11.2” x 14.9”) | 80μm | 0.5 mm (0.0196”) |

Our Commitment to High Standards in SLA 3D Printing

At Modo Rapid, we produce your custom parts with strict adherence to our manufacturing standards, ensuring that all parts and processes comply with our rigorous quality guidelines. A detailed verification of these requirements is provided in the inspection report included with every order.

Parts are fully cured according to the material manufacturer’s specifications before shipment.

Hollow sections are thoroughly drained of any excess resin.

All support structures are removed, and any remaining support marks are meticulously sanded smooth.

Pros & Cons of 3D Printing

SLA 3D printing shines when it comes to producing parts with exceptional dimensional accuracy and intricate details. The smooth surface finish of SLA parts makes them perfect for visual prototypes. Additionally, SLA offers a variety of specialty materials, including clear, flexible, and castable resins, providing versatility for different applications.

However, it’s important to note some limitations. SLA parts tend to be brittle, which means they might not be ideal for functional prototypes, although industrial SLA can create more durable components suitable for this stage. Over time, the mechanical properties and visual appeal of SLA parts can deteriorate when exposed to sunlight. Another consideration is that SLA always requires support structures, and post-processing is needed to remove any visual marks left by these supports.

Design Guidelines for SLA 3D Printing

When designing parts for SLA 3D printing, it’s essential to consider certain technical specifications to achieve the best results. The table below outlines the recommended and technically feasible sizes for some of the most common features in SLA 3D printed parts. For unsupported walls, a thickness of 1.0 mm (0.0393 in) is recommended, while supported walls can be as thin as 0.5 mm (0.0197 in). The minimum feature size that can be accurately printed is 0.2 mm (0.00787 in), and the smallest hole diameter should be at least 0.5 mm (0.0197 in). Additionally, for escape holes, a minimum diameter of 4.0 mm (0.157 in) is advised.

1 Free Sample for First-Time Customers

Getting free samples is the best way to inspect suppliers

Production Feasibility Analysis

Before moving into full production, we conduct a comprehensive feasibility analysis to ensure that your design can be efficiently manufactured at scale. This step involves evaluating the materials, manufacturing processes, and potential challenges to ensure a smooth transition from prototype to production. Our team will collaborate closely with you to refine your design, optimize for manufacturability, and mitigate risks.

Before moving into full production, we conduct a comprehensive feasibility analysis to ensure that your design can be efficiently manufactured at scale. This step involves evaluating the materials, manufacturing processes, and potential challenges to ensure a smooth transition from prototype to production. Our team will collaborate closely with you to refine your design, optimize for manufacturability, and mitigate risks.

3D printing

Our 3D printing services offer rapid prototyping with precision and flexibility, allowing you to quickly test and iterate on your designs. We provide a range of 3D printing technologies, including SLA, SLS, and FDM, to match your specific needs, whether you require detailed models or functional parts. This stage is crucial for validating design concepts before moving to more advanced manufacturing processes.

Our 3D printing services offer rapid prototyping with precision and flexibility, allowing you to quickly test and iterate on your designs. We provide a range of 3D printing technologies, including SLA, SLS, and FDM, to match your specific needs, whether you require detailed models or functional parts. This stage is crucial for validating design concepts before moving to more advanced manufacturing processes.

Urethane Casting

For low to medium volume production, urethane casting offers a cost-effective solution with high fidelity to the original prototype. This process is ideal for creating durable, flexible parts that closely resemble injection-molded components. We use high-quality silicone molds and urethane resins to produce parts with excellent surface finishes and physical properties.

For low to medium volume production, urethane casting offers a cost-effective solution with high fidelity to the original prototype. This process is ideal for creating durable, flexible parts that closely resemble injection-molded components. We use high-quality silicone molds and urethane resins to produce parts with excellent surface finishes and physical properties.

Injection Molding

When you’re ready for large-scale production, our injection molding services ensure consistent, high-quality parts with efficient turnaround times. We specialize in both prototype and production molds, offering a variety of materials to suit your product’s needs. From small batches to full-scale production, our injection molding capabilities are designed to meet your demands.

When you’re ready for large-scale production, our injection molding services ensure consistent, high-quality parts with efficient turnaround times. We specialize in both prototype and production molds, offering a variety of materials to suit your product’s needs. From small batches to full-scale production, our injection molding capabilities are designed to meet your demands.

We Help You Go From Prototype To Production

Quality Checks at Every Stage for Your Parts

Initial Material Inspection:

Equipment: Optical Emission Spectrometer (OES) or X-ray Fluorescence (XRF) Analyzer. Purpose: Verify the composition and quality of raw materials before production begins.

In-Process Dimensional Inspection:

Equipment: Coordinate Measuring Machine (CMM) and Vernier Calipers. Purpose: Ensure parts meet dimensional specifications during various stages of machining.

Surface Finish Inspection:

Equipment: Surface Roughness Tester. Purpose: Check the surface texture and finish to meet the required standards.

Final Quality Inspection:

Equipment: ZEISS Coordinate Measuring Machine (CMM) and Optical Comparator. Purpose: Conduct a comprehensive inspection of the finished part to verify all dimensions, tolerances, and overall quality.

2 ZEISS CMMs for your project 24/7

We are a 24-hour facility with technicians working 3 shifts. For many of our customer’s urgent projects, we use our 2 ZEISS CMM’s to inspect the parts and make sure your project goes smoothly.

Quality Inspections We Perform for Your Parts

Rapid Printing According To Your Needs

Prototypes: 1-7 Days Lead Time

Small Batches: 7-10 Days Lead Time

Large Volumes: 10-30 Days Lead Time

100% China factory price, no middleman

24 hours factory operation, feel free to contact us

Frequently Ask Questions

Modo Rapid ensures fast delivery, with 3D printed parts typically shipped within as little as one day, depending on the complexity and material chosen. This rapid turnaround helps accelerate your design process and reduces time to market.

Our 3D printing services are certified under ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D standards. These certifications guarantee that our manufacturing processes meet the highest quality standards, essential for industries like aerospace, automotive, and medical devices.

Modo Rapid provides a wide range of 3D printing technologies, including Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), Stereolithography (SLA), Direct Metal Laser Sintering (DMLS), PolyJet, Carbon DLS, Nexa3D LSPc, and Metal Binder Jetting. These options are tailored for various applications, from rapid prototyping to high-quality production parts.

Modo Rapid can print parts up to 24″ x 36″ x 36″ in size without the need to split and bond, ideal for large prototypes or complex components.

Yes, Modo Rapid offers Design for Manufacturability (DFM) services. Our engineers can work with you to optimize your designs, ensuring they are ready for efficient production while minimizing material waste and reducing overall costs.

We provide a variety of post-processing options, including anodizing, powder coating, polishing, and more, to enhance the durability, appearance, and functionality of your parts. We can also handle complex assembly and finishing tasks to deliver a final product that meets your precise needs.leo.

We prioritize your privacy and security. All uploaded files are kept confidential, and we can provide non-disclosure agreements (NDAs) to ensure that your intellectual property is fully protected throughout the manufacturing process.

Our manufacturing process is certified under ISO 9001:2015 and IATF 16949:2016, ensuring that each part meets stringent quality standards. We use advanced inspection tools like CMMs (Coordinate Measuring Machines) and laser scanners to verify the precision and accuracy of your parts before delivery.

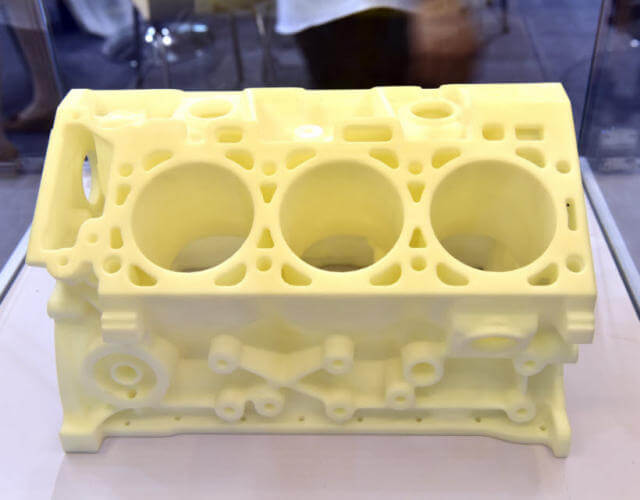

Concept Models

SLA 3D printing is ideal for producing highly detailed concept models. Its precision and excellent surface finish make it perfect for visualizing and refining product designs early in the development process. Engineers and designers can create physical representations of their ideas, enabling better communication and iteration.

Rapid Prototyping

SLA’s ability to create accurate and functional prototypes quickly is invaluable in industries like automotive, aerospace, and electronics. By using SLA, companies can accelerate their product development cycles, allowing for rapid testing, validation, and refinement of designs. This is especially beneficial for creating parts that require fine details and tight tolerances.

Medical and Dental Applications

In the medical and dental fields, SLA is used to produce custom anatomical models, surgical guides, and dental restorations with high precision. The technology allows for the creation of patient-specific models that improve surgical planning and outcomes. Additionally, dental professionals use SLA to fabricate crowns, bridges, and orthodontic appliances that fit perfectly.

Jewelry and Fashion Design

SLA’s precision is also highly valued in the jewelry and fashion industries. Designers use SLA to create intricate patterns and delicate designs that would be difficult to achieve with traditional manufacturing methods. The ability to produce detailed molds and prototypes allows for greater creativity and customization in jewelry and fashion pieces.

Engineering and Aerospace Applications

SLA is widely used in engineering and aerospace for creating accurate prototypes and functional parts. The technology’s ability to produce complex geometries and fine details makes it suitable for developing lightweight, aerodynamic components that are critical in these industries. SLA is often employed to create wind tunnel models, test parts, and even end-use components that meet strict performance requirements.

Consumer Goods

For consumer goods, SLA’s high-resolution printing capabilities allow manufacturers to produce high-quality, aesthetically pleasing products. The smooth surface finish and precision of SLA prints make them ideal for final prototypes and even small-scale production runs of consumer products, such as electronics housings, cosmetic packaging, and more.

SLA 3D printing’s versatility, precision, and ability to produce high-quality parts with complex geometries make it an essential tool across various industries, from rapid prototyping to final product manufacturing.

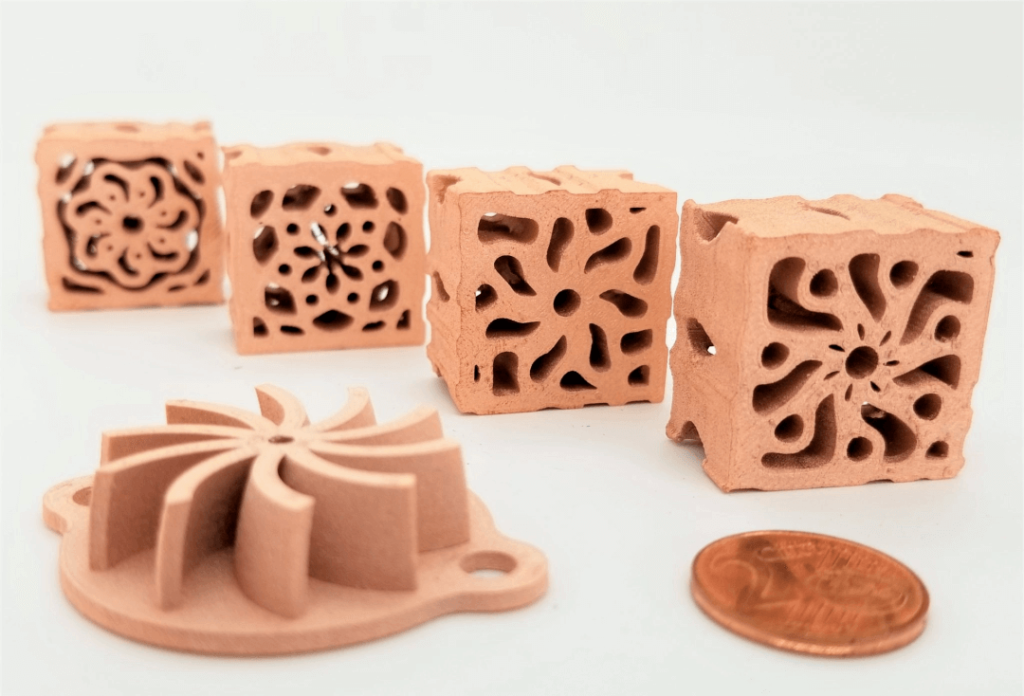

Bronze 3D Printing Service

Receive quick quotes for parts made from over 70 different metal and plastic materials. All orders comply with ISO 9001:2015, IATF 16949:2016 certifications. Availability may vary, and we cannot always guarantee this service at all times.

Color 3D Printing Service by Modo Rapid

Get instant quotes online for parts made from over 70 metal and plastic materials.

Large Scale 3D Printing Service

Get quotes for large-scale 3D printed parts, available in over 70 different metal and plastic materials.