Industrial 3D Printing Services

Table of Contents

3D Printing Services We Offer You

Stereolithography (SLA)

A high-resolution, production-grade technology.

SLA is known for its high precision and can achieve tolerances as tight as ±0.05 mm, making it ideal for detailed prototypes and intricate designs

PolyJet

Ideal for visual models or functional prototypes.

PolyJet technology also offers high precision, with tolerances generally around ±0.1 mm. This method excels at creating smooth surfaces and detailed parts with multiple materials

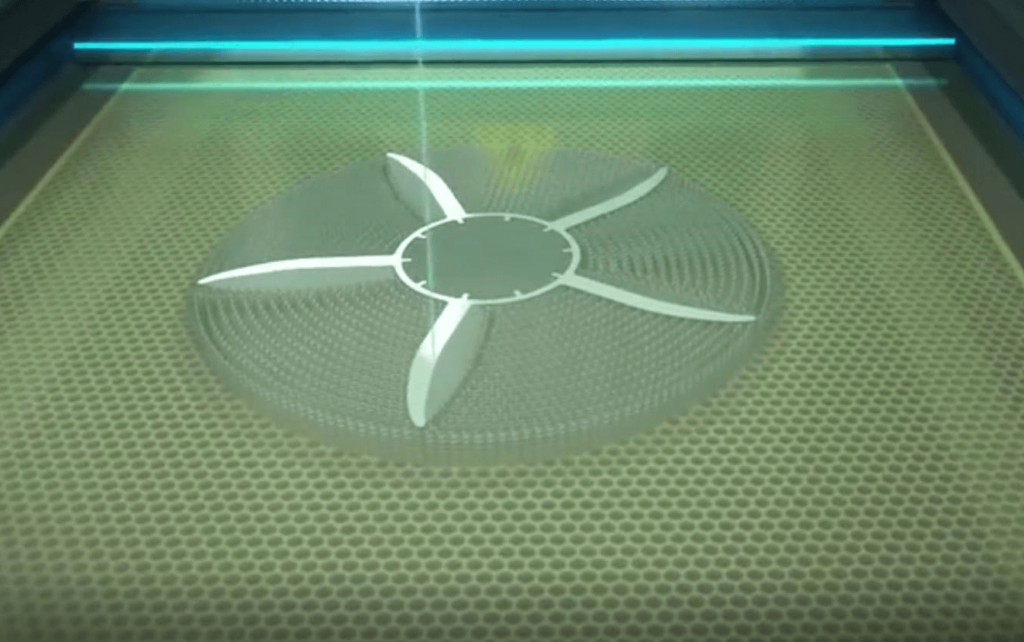

Selective Laser Sintering (SLS)

Ideal for functional testing, low to mid volumes.

SLS is effective for producing functional prototypes with tolerances typically around ±0.3 mm or ±0.3% of the part size, which makes it suitable for more complex geometries

Multi Jet Fusion (MJF)

Accelerate time to market with production-grade 3D printing.

MJF provides good accuracy, with tolerances generally around ±0.1 mm for the first inch and ±0.005 inch per additional inch

Fused Deposition Modeling (FDM)

Low-cost process for early-stage prototypes.

FDM is less precise compared to other methods, with typical tolerances ranging from ±0.1 mm to ±0.3 mm, depending on the material and part size. This method is more suited for less detailed prototypes or when lower costs are a priority

Digital Light Synthesis (DLS)

Production speed and repeatability for end-use parts.

DLS is comparable to SLA in terms of precision, with tolerances around ±0.1 mm, offering high accuracy for parts with complex geometries and mechanical properties

Modo Rapid offers seamless access to premium 3D printing services, utilizing cutting-edge additive manufacturing technologies.

Choose from over 40 materials and 11 finishing options to perfectly match the requirements of any project.

Choose from Over 80 Metal and Plastic Materials

ABS is a durable thermoplastic with good impact resistance and toughness, making it suitable for functional prototypes and end-use parts in a wide range of applications, including automotive components, consumer products, and electronics housings.

Process: FDM (Fused Deposition Modeling)

Color: Various

Resolution: 0.2 mm

Max Print Size: 305 x 305 x 305 mm

ABS-M30i is a biocompatible thermoplastic that offers excellent strength and toughness, making it ideal for medical and food packaging applications that require sterilization and FDA compliance.

Process: FDM (Fused Deposition Modeling)

Color: White

Resolution: 0.178 mm

Max Print Size: 406 x 355 x 406 mm

ABS ESD is an electrostatic discharge-safe material, designed for applications that require protection from static electricity, such as electronic component handling and packaging.

Process: FDM (Fused Deposition Modeling)

Color: Black

Resolution: 0.254 mm

Max Print Size: 914 x 610 x 914 mm

ABS-Like resin offers similar properties to standard ABS plastic, with a smooth surface finish, making it ideal for prototyping and functional testing of parts that require moderate strength and durability.

Process: SLA (Stereolithography)

Color: White

Resolution: 0.1 mm

Max Print Size: 145 x 145 x 175 mm

PLA is a biodegradable thermoplastic derived from renewable resources, offering good strength and stiffness for general-purpose 3D printing, ideal for prototypes, models, and low-wear applications.

Process: FDM (Fused Deposition Modeling)

Color: Various

Resolution: 0.2 mm

Max Print Size: 220 x 220 x 250 mm

PETG combines the strength of ABS with the ease of use of PLA, offering excellent chemical resistance and impact strength, making it suitable for functional prototypes and mechanical parts.

Process: FDM (Fused Deposition Modeling)

Color: Transparent, Various

Resolution: 0.2 mm

Max Print Size: 220 x 220 x 250 mm

Nylon is a strong and durable thermoplastic with excellent mechanical properties, ideal for parts requiring toughness, flexibility, and wear resistance, such as gears, bearings, and functional prototypes.

Process: SLS (Selective Laser Sintering)

Color: White, Black

Resolution: 0.1 mm

Max Print Size: 300 x 300 x 300 mm

TPU is a flexible material known for its elasticity and durability, suitable for applications requiring rubber-like properties, such as gaskets, seals, and wearable prototypes.

Process: FDM (Fused Deposition Modeling)

Color: Black, Natural

Resolution: 0.254 mm

Max Print Size: 914 x 610 x 914 mm

PC is a strong, impact-resistant material with high thermal resistance, making it ideal for tough, durable parts in demanding applications like automotive, aerospace, and industrial components.

Process: FDM (Fused Deposition Modeling)

Color: Transparent, Various

Resolution: 0.178 mm

Max Print Size: 406 x 355 x 406 mm

PEEK is a high-performance thermoplastic with exceptional mechanical and chemical resistance properties, suitable for aerospace, automotive, and medical applications that require extreme performance.

Process: FDM (Fused Deposition Modeling)

Color: Natural (Beige)

Resolution: 0.2 mm

Max Print Size: 165 x 165 x 165 mm

PP is a lightweight, flexible material with excellent chemical resistance, commonly used for automotive parts, living hinges, and fluid containers.

Process: FDM (Fused Deposition Modeling)

Color: Natural, White

Resolution: 0.2 mm

Max Print Size: 200 x 200 x 200 mm

HIPS is a versatile, impact-resistant material often used as a support material for ABS or as a standalone material for parts requiring good toughness and machinability.

Process: FDM (Fused Deposition Modeling)

Color: White

Resolution: 0.2 mm

Max Print Size: 305 x 305 x 305 mm

Standard Resin is a versatile photopolymer offering smooth surface finishes and high detail. Ideal for creating visual prototypes and intricate designs, it is commonly used in industries such as consumer goods and healthcare.

- Process: SLA, DLP

- Color: Translucent, White

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 145 x 145 x 175 mm

Tough Resin is engineered to withstand high stress and strain, making it suitable for functional prototypes and tooling that require durability. It mimics the mechanical properties of ABS plastic.

- Process: SLA, DLP

- Color: Grey, Black

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 145 x 145 x 175 mm

Flexible Resin is designed for parts that need to bend and flex under stress. It is perfect for prototyping soft-touch components, grips, and seals.

- Process: SLA, DLP

- Color: Black, White

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 145 x 145 x 175 mm

High-Temperature Resin can withstand extreme temperatures, making it ideal for applications that involve heat exposure, such as molds and testing environments.

- Process: SLA, DLP

- Color: Amber

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 145 x 145 x 175 mm

Stainless Steel is a durable metal known for its excellent strength, corrosion resistance, and heat tolerance. It’s commonly used in medical devices, aerospace components, and industrial tools.

- Process: DMLS (Direct Metal Laser Sintering)

- Color: Metallic Grey

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 250 x 250 x 325 mm

Aluminum offers a balance of lightweight properties and good strength, making it suitable for aerospace parts, automotive components, and structural applications.

- Process: DMLS, SLM (Selective Laser Melting)

- Color: Metallic Grey

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 250 x 250 x 325 mm

Titanium is known for its high strength-to-weight ratio and excellent corrosion resistance, making it ideal for aerospace, medical implants, and high-performance automotive parts.

- Process: DMLS, SLM

- Color: Metallic Grey

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 250 x 250 x 325 mm

Inconel is a superalloy known for its excellent performance in extreme environments, including high temperatures and corrosive conditions. It’s commonly used in aerospace, chemical processing, and gas turbines.

- Process: DMLS, SLM

- Color: Metallic Grey

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 250 x 250 x 325 mm

Cobalt-Chrome is a high-strength, wear-resistant metal used in dental and orthopedic implants, as well as in high-temperature environments like gas turbines.

- Process: DMLS, SLM

- Color: Metallic Grey

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 250 x 250 x 325 mm

Copper is known for its excellent electrical conductivity and thermal properties, making it suitable for electrical components, heat exchangers, and architectural applications.

- Process: DMLS

- Color: Metallic Copper

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 250 x 250 x 325 mm

Silver is used for its conductivity, antimicrobial properties, and aesthetic appeal, making it ideal for electronics, medical devices, and jewelry.

- Process: DMLS

- Color: Metallic Silver

- Resolution: 0.05 – 0.1 mm

- Max Print Size: 250 x 250 x 325 mm

Carbon Fiber Reinforced Plastics combine the strength and stiffness of carbon fibers with the versatility of plastic, providing lightweight and strong parts ideal for aerospace, automotive, and sporting goods.

- Process: FDM, SLA, SLS

- Color: Black

- Resolution: 0.1 – 0.2 mm

- Max Print Size: 914 x 610 x 914 mm

Advanced 3D Printing Solutions for Engineering

Access top-quality printed components at every stage of your product development.

Compare Materials for Optimal Performance

Explore material properties and filter by application during your setup process with material cards.Optimize Infill Density

Adjust infill density in the settings menu to balance cost and structural integrity for FDM parts.Enhance Thread Strength

Include optional configurations for threaded inserts by uploading your drawing with marked hardware locations.

1 Free Sample for First-Time Customers

Getting free samples is the best way to inspect suppliers

Production Feasibility Analysis

Before moving into full production, we conduct a comprehensive feasibility analysis to ensure that your design can be efficiently manufactured at scale. This step involves evaluating the materials, manufacturing processes, and potential challenges to ensure a smooth transition from prototype to production. Our team will collaborate closely with you to refine your design, optimize for manufacturability, and mitigate risks.

Before moving into full production, we conduct a comprehensive feasibility analysis to ensure that your design can be efficiently manufactured at scale. This step involves evaluating the materials, manufacturing processes, and potential challenges to ensure a smooth transition from prototype to production. Our team will collaborate closely with you to refine your design, optimize for manufacturability, and mitigate risks.

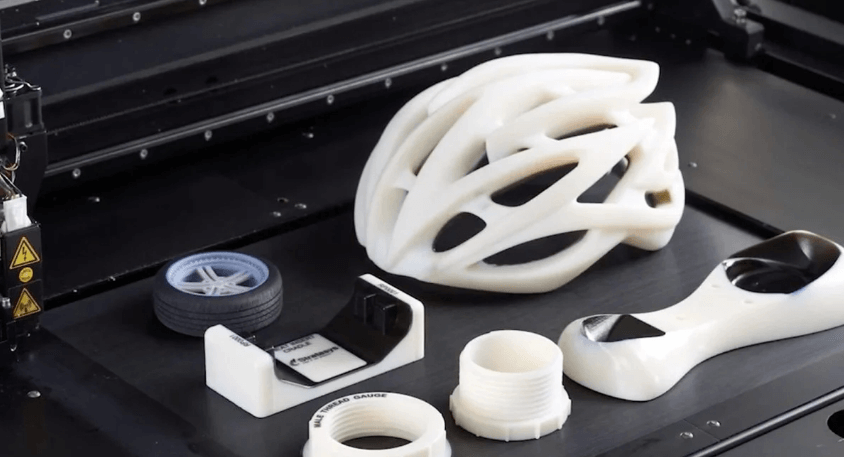

3D printing

Our 3D printing services offer rapid prototyping with precision and flexibility, allowing you to quickly test and iterate on your designs. We provide a range of 3D printing technologies, including SLA, SLS, and FDM, to match your specific needs, whether you require detailed models or functional parts. This stage is crucial for validating design concepts before moving to more advanced manufacturing processes.

Our 3D printing services offer rapid prototyping with precision and flexibility, allowing you to quickly test and iterate on your designs. We provide a range of 3D printing technologies, including SLA, SLS, and FDM, to match your specific needs, whether you require detailed models or functional parts. This stage is crucial for validating design concepts before moving to more advanced manufacturing processes.

Urethane Casting

For low to medium volume production, urethane casting offers a cost-effective solution with high fidelity to the original prototype. This process is ideal for creating durable, flexible parts that closely resemble injection-molded components. We use high-quality silicone molds and urethane resins to produce parts with excellent surface finishes and physical properties.

For low to medium volume production, urethane casting offers a cost-effective solution with high fidelity to the original prototype. This process is ideal for creating durable, flexible parts that closely resemble injection-molded components. We use high-quality silicone molds and urethane resins to produce parts with excellent surface finishes and physical properties.

Injection Molding

When you’re ready for large-scale production, our injection molding services ensure consistent, high-quality parts with efficient turnaround times. We specialize in both prototype and production molds, offering a variety of materials to suit your product’s needs. From small batches to full-scale production, our injection molding capabilities are designed to meet your demands.

When you’re ready for large-scale production, our injection molding services ensure consistent, high-quality parts with efficient turnaround times. We specialize in both prototype and production molds, offering a variety of materials to suit your product’s needs. From small batches to full-scale production, our injection molding capabilities are designed to meet your demands.

We Help You Go From Prototype To Production

Quality Checks at Every Stage for Your Parts

Initial Material Inspection:

Equipment: Optical Emission Spectrometer (OES) or X-ray Fluorescence (XRF) Analyzer. Purpose: Verify the composition and quality of raw materials before production begins.

In-Process Dimensional Inspection:

Equipment: Coordinate Measuring Machine (CMM) and Vernier Calipers. Purpose: Ensure parts meet dimensional specifications during various stages of machining.

Surface Finish Inspection:

Equipment: Surface Roughness Tester. Purpose: Check the surface texture and finish to meet the required standards.

Final Quality Inspection:

Equipment: ZEISS Coordinate Measuring Machine (CMM) and Optical Comparator. Purpose: Conduct a comprehensive inspection of the finished part to verify all dimensions, tolerances, and overall quality.

2 ZEISS CMMs for your project 24/7

We are a 24-hour facility with technicians working 3 shifts. For many of our customer’s urgent projects, we use our 2 ZEISS CMM’s to inspect the parts and make sure your project goes smoothly.

Quality Inspections We Perform for Your Parts

Rapid Printing According To Your Needs

Prototypes: 1-7 Days Lead Time

Small Batches: 7-10 Days Lead Time

Large Volumes: 10-30 Days Lead Time

100% China factory price, no middleman

24 hours factory operation, feel free to contact us

Frequently Ask Questions

Modo Rapid ensures fast delivery, with 3D printed parts typically shipped within as little as one day, depending on the complexity and material chosen. This rapid turnaround helps accelerate your design process and reduces time to market.

Our 3D printing services are certified under ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D standards. These certifications guarantee that our manufacturing processes meet the highest quality standards, essential for industries like aerospace, automotive, and medical devices.

Modo Rapid provides a wide range of 3D printing technologies, including Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), Stereolithography (SLA), Direct Metal Laser Sintering (DMLS), PolyJet, Carbon DLS, Nexa3D LSPc, and Metal Binder Jetting. These options are tailored for various applications, from rapid prototyping to high-quality production parts.

Modo Rapid can print parts up to 24″ x 36″ x 36″ in size without the need to split and bond, ideal for large prototypes or complex components.

Yes, Modo Rapid offers Design for Manufacturability (DFM) services. Our engineers can work with you to optimize your designs, ensuring they are ready for efficient production while minimizing material waste and reducing overall costs.

We provide a variety of post-processing options, including anodizing, powder coating, polishing, and more, to enhance the durability, appearance, and functionality of your parts. We can also handle complex assembly and finishing tasks to deliver a final product that meets your precise needs.leo.

We prioritize your privacy and security. All uploaded files are kept confidential, and we can provide non-disclosure agreements (NDAs) to ensure that your intellectual property is fully protected throughout the manufacturing process.

Our manufacturing process is certified under ISO 9001:2015 and IATF 16949:2016, ensuring that each part meets stringent quality standards. We use advanced inspection tools like CMMs (Coordinate Measuring Machines) and laser scanners to verify the precision and accuracy of your parts before delivery.

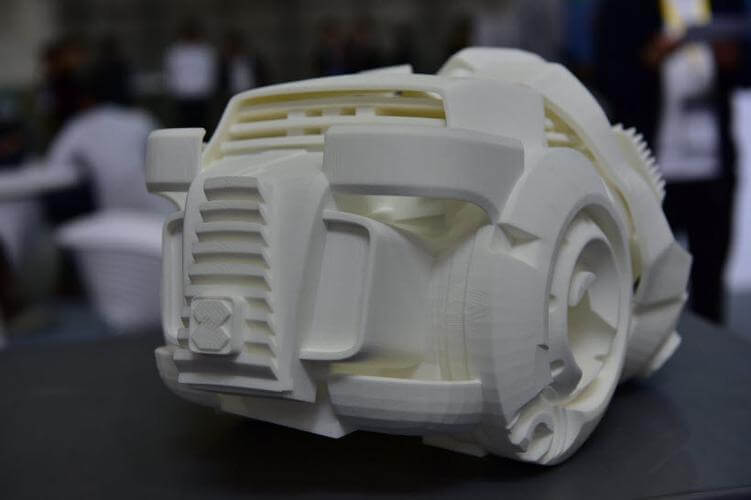

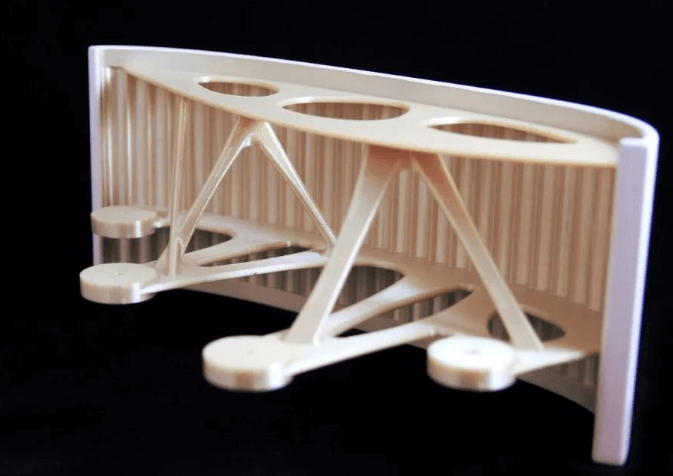

Advantages of 3D Printing

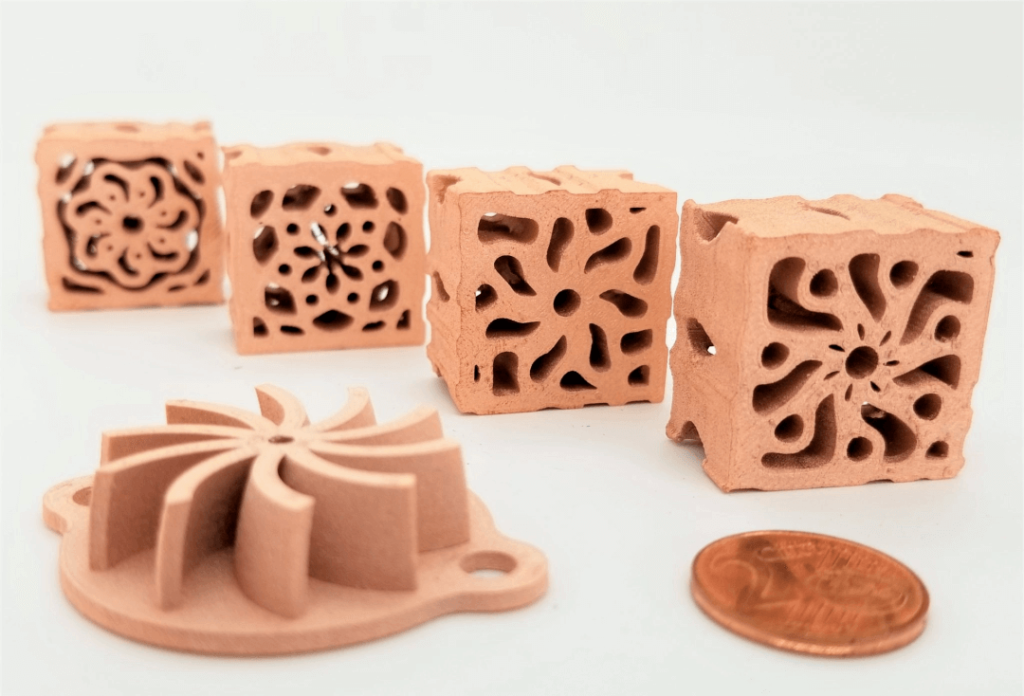

3D printing allows for the production of intricate designs that are difficult or impossible to achieve with traditional manufacturing methods. This capability is especially useful in industries like aerospace and automotive, where lightweight structures with complex internal features are needed.

The technology is ideal for creating customized products, especially in the medical field where personalized implants, prosthetics, and surgical tools are becoming more common.

3D printing speeds up the prototyping process, allowing designers to iterate quickly. A prototype can often be created in just a few hours, enabling faster development cycles.

Unlike traditional subtractive manufacturing, which involves cutting away material, 3D printing is an additive process that only uses the material necessary to build the part, leading to minimal waste.

Parts can be produced as needed, without the need for large inventories. This reduces storage costs and allows for just-in-time manufacturing.

The reduced material waste and the use of recyclable materials make 3D printing a more sustainable manufacturing option.

For small production runs or highly complex parts, 3D printing is often more cost-effective than traditional manufacturing methods.

With fewer design constraints, 3D printing offers more freedom for engineers to create innovative solutions without the limitations of traditional manufacturing methods.

Bronze 3D Printing Service

Receive quick quotes for parts made from over 70 different metal and plastic materials. All orders comply with ISO 9001:2015, IATF 16949:2016 certifications. Availability may vary, and we cannot always guarantee this service at all times.

Color 3D Printing Service by Modo Rapid

Get instant quotes online for parts made from over 70 metal and plastic materials.

Large Scale 3D Printing Service

Get quotes for large-scale 3D printed parts, available in over 70 different metal and plastic materials.