CNC Machining Copper

- Exceptional Corrosion and Conductivity: Ideal for electronics, automotive, and aerospace industries.

- Precision:0.001mm

- Fast Turnaround Times: Receive your parts in just 1-7 days

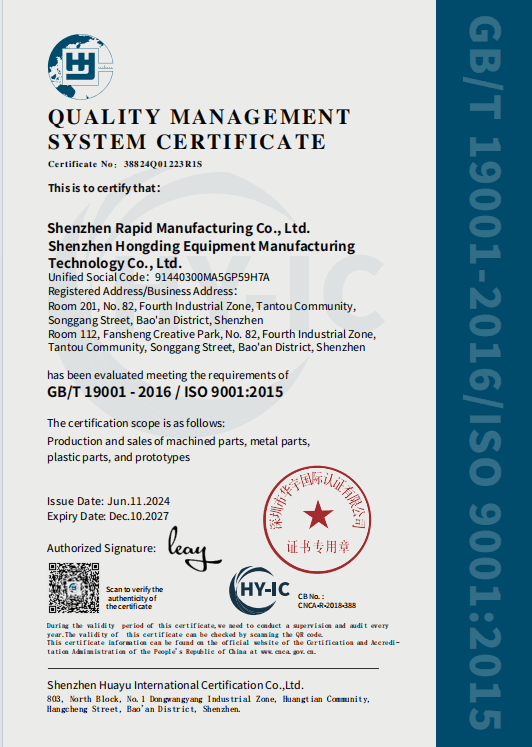

- Certified Quality: ISO9001:2015 and IATF16949 certified processes for top-quality results.

Ensuring ±0.001mm Precision in CNC Copper Machining

At Modo Rapid, we offer high precision in our machining processes, with achievable tolerances up to ±0.001 mm.

Our commitment to tight tolerances ensures that your components meet the strictest standards, vital for your critical applications.

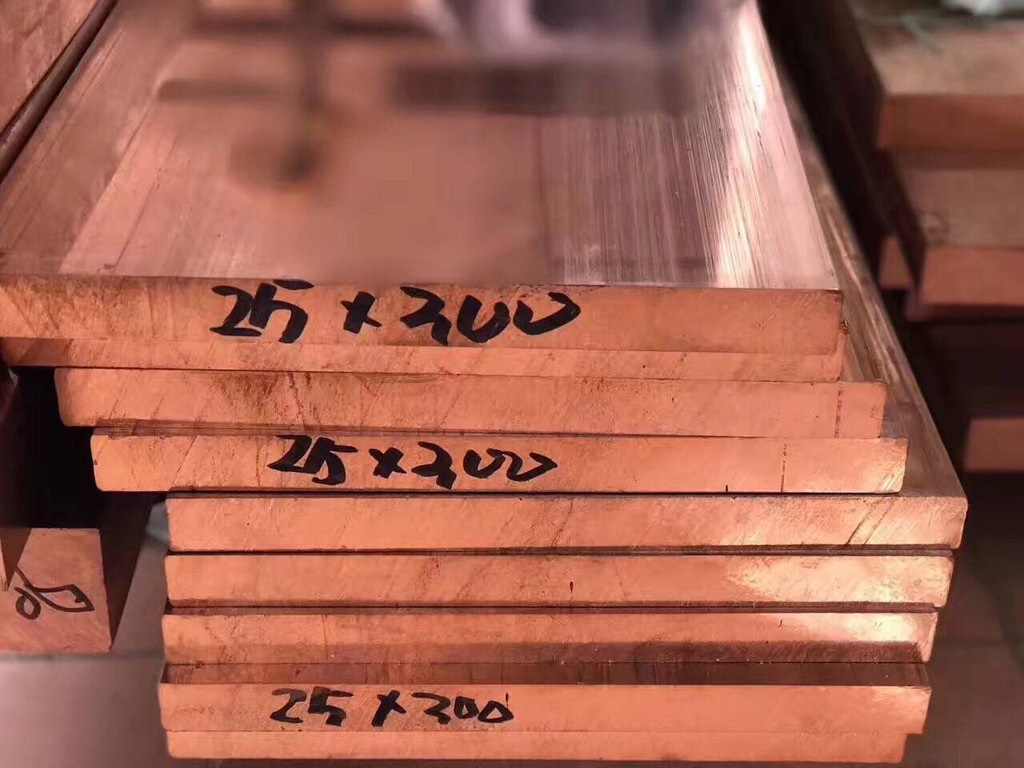

Copper Material Selection

Which copper alloy is best for my application and what are the differences between various types?

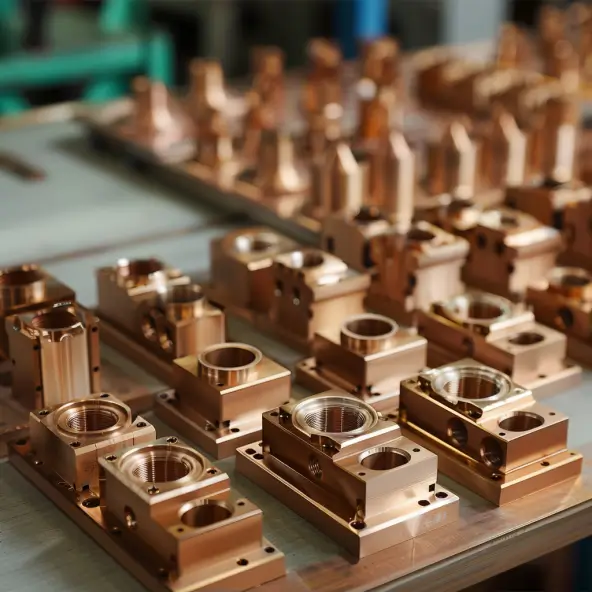

Selecting the right copper alloy for your application is crucial for ensuring optimal performance and durability. Copper alloys are known for their excellent electrical and thermal conductivity, corrosion resistance, and machinability. Here are some common copper alloys and their uses:

- C110 (Electrolytic Tough Pitch Copper): Pure copper with excellent electrical conductivity, commonly used in electrical and electronic applications.

- C101 (Oxygen-Free Copper): High-purity copper with superior electrical and thermal conductivity, ideal for high-performance electrical and electronic applications.

- C145 (Tellurium Copper): Copper alloy with tellurium, offering improved machinability while retaining good electrical conductivity, used in connectors and electrodes.

- C182 (Chromium Copper): High-strength copper alloy with good conductivity, used in resistance welding and electrical applications.

- C172 (Beryllium Copper): High-strength, corrosion-resistant copper alloy with good conductivity, ideal for aerospace and military applications.

- C464 (Naval Brass): Copper alloy with zinc and tin, offering good corrosion resistance and strength, used in marine and industrial applications.

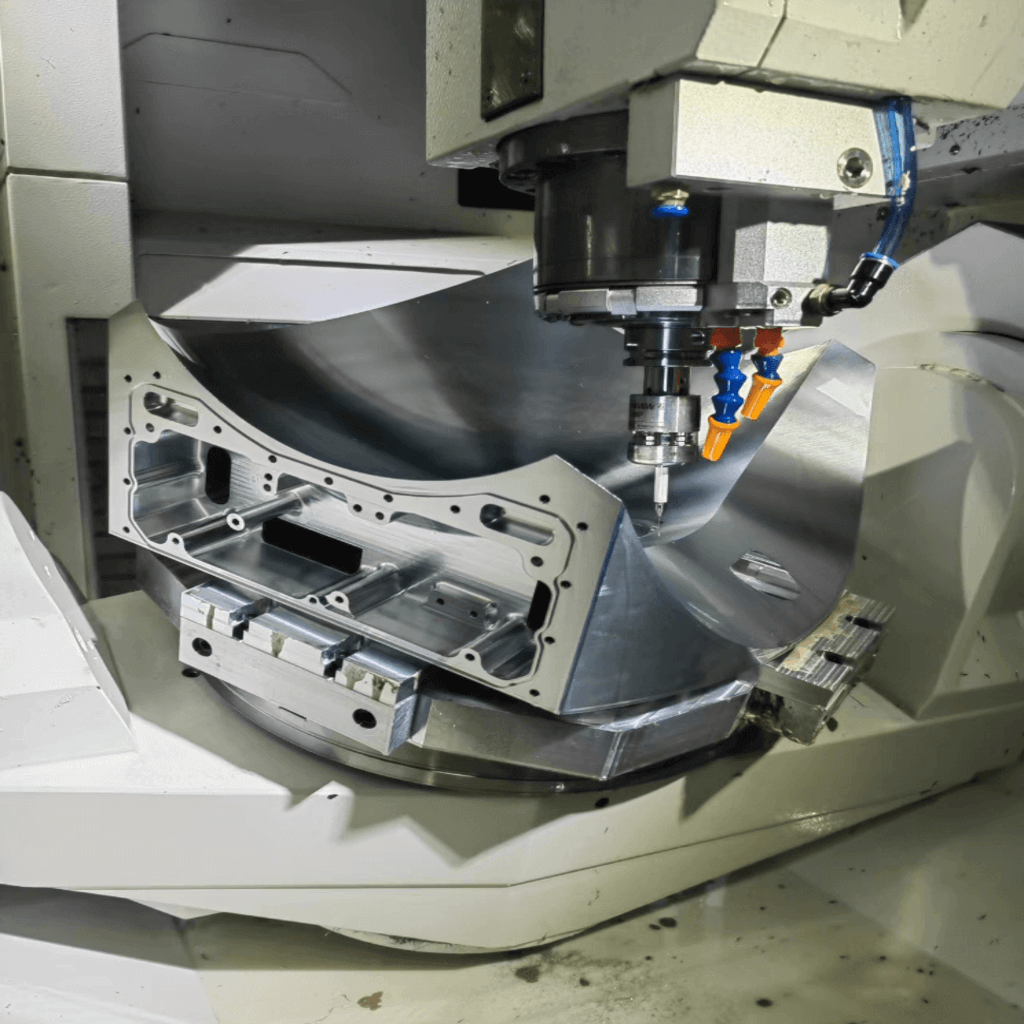

How Modo Rapid Ensures Your Copper Parts Remain Deformation-Free

Copper is a versatile material, but machining it requires special attention. At Modo Rapid, we prioritize your needs and ensure your copper alloy parts maintain their integrity throughout the CNC machining process.

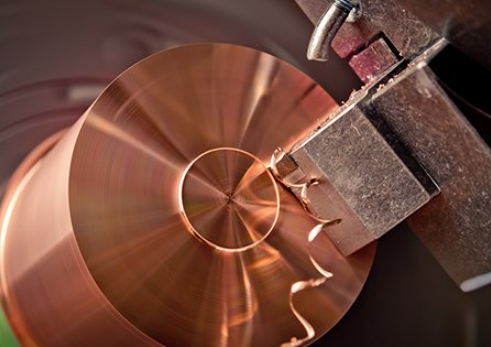

Heat Buildup

Copper alloys are softer than many materials, leading to potential deformation under high heat. We manage this by optimizing the CNC machine RPM and using a larger chipload. Our high-pressure coolant systems ensure the cutting tools remain cool and effective, delivering high-quality copper parts for you.

Galling

Copper can become sticky and adhere to the cutting tool. To prevent this, we use high-pressure coolant and ensure swift chip removal. This mitigates heat buildup and extends tool life, delivering precise parts that meet your specifications.

Workholding

Copper’s malleability requires a firm grip during CNC machining. We maintain a tight hold and ensure constant tool motion without interruptions. This prevents deformation and guarantees that your parts are machined to perfection.

At Modo Rapid, we understand the challenges of machining copper and employ expert techniques to ensure your parts remain flawless and deformation-free.

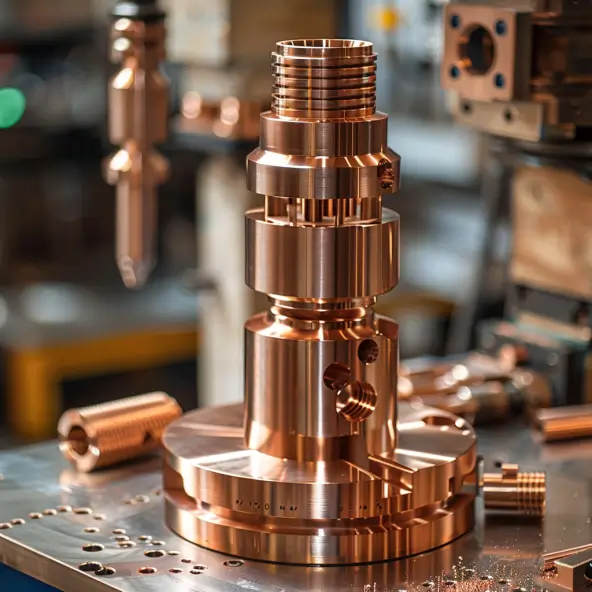

What are the maximum part sizes and complex geometries you can handle?

- Part Sizes: We can machine parts with maximum dimensions of 1500mm x 800mm x 600mm, meeting the needs of most industrial applications.

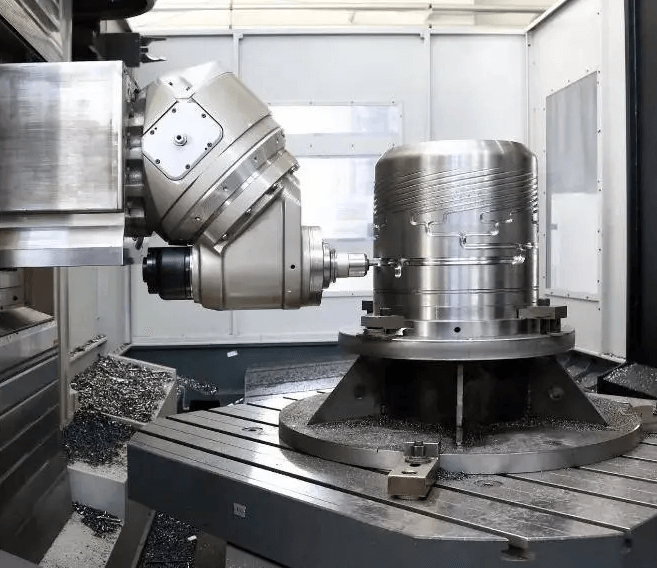

- Complex Geometries: Our 5-axis and 4-axis CNC machining centers can precisely machine complex geometries, including internal channels, intricate surfaces, and high-precision apertures. Our equipment can manage fine features and tight tolerances, ensuring your design intentions are perfectly realized.

What advanced CNC equipment do you have for machining copper alloys?

- 5-Axis CNC Machining Centers: Capable of producing complex geometries and intricate designs, ensuring high accuracy and smooth finishes on copper components.

- High-Speed CNC Mills: Equipped with robust spindles and high feed rates, ideal for efficiently machining copper while maintaining tight tolerances.

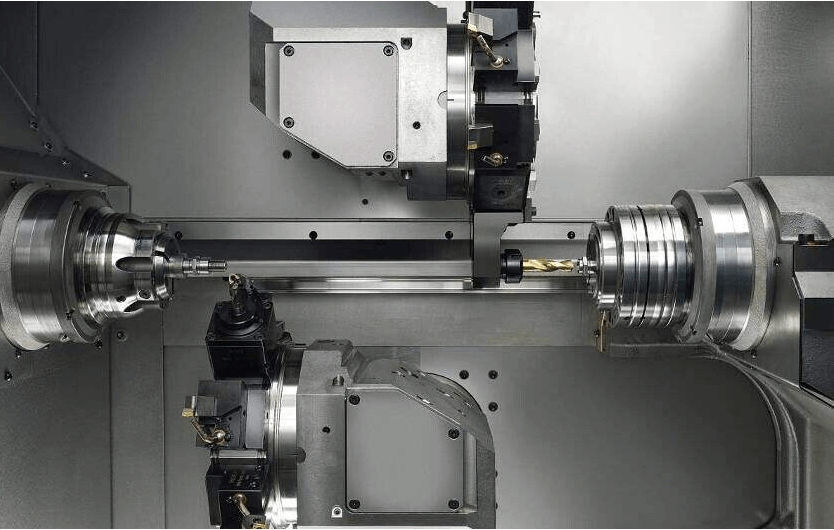

- Multi-Tasking CNC Lathes: These machines combine milling and turning capabilities, allowing for versatile and efficient production of copper parts in a single setup.

- Precision CNC Grinders: Essential for achieving the fine surface finishes and exact dimensions required for high-performance copper components.

- EDM (Electrical Discharge Machining): Utilized for cutting intricate shapes and hard-to-machine areas, providing high precision without inducing stress in the copper material.

- Mill-turn machine: Combines turning and milling functions in one, completing complex multi-axis machining on a single setup. It improves accuracy and efficiency, ideal for high-precision parts. For copper alloy parts, its high rigidity and multi-axis capabilities reduce machining time and ensure quality. Using efficient tools and optimized parameters further enhances production speed and reliability.

Copper Parts Finishes

Surface Finish Options

- Smoothing

- Polishing

- Bead blasting

- Brushing

- Painting

- Chroming

- Metallizing

- PVD coating

- Powder coating

- Electrophoresis

Impact of Surface Preparation on Copper Parts

Surface preparation significantly influences both the performance and appearance of copper parts:

- Enhanced Durability: Proper surface preparation can increase the lifespan of copper parts by improving resistance to corrosion and wear.

- Improved Functionality: A well-prepared surface can reduce friction and improve the efficiency of mechanical components.

- Aesthetic Appeal: High-quality finishes enhance the visual appeal of copper parts, making them suitable for both functional and decorative applications.

- Adhesion of Coatings: Proper preparation ensures better adhesion of subsequent coatings or treatments, ensuring consistent and long-lasting finishes.

Cost Calculation for Custom Copper Alloy Parts

The cost of machining copper parts at Modo Rapid is determined by several key factors:

- Material Costs: The price of copper, which varies based on the alloy, is a significant factor.

- Complexity of Design: Parts with intricate designs and tight tolerances require more time and specialized tools, increasing costs.

- Machining Time: Longer machining times due to the specific properties of copper and the need for precise operations.

- Surface Finishes: Additional processes such as anodizing, polishing, or coating add to the total cost.

- Tool Wear: Copper’s properties can lead to faster tool wear, contributing to higher tool replacement costs.

Volume Discounts and Minimum Order Quantity

At Modo Rapid, we offer volume discounts to accommodate larger production runs. The discounts increase with the order size, making it more cost-effective for bulk purchases. We understand the diverse needs of our clients, so we have set a flexible minimum order quantity to cater to both small and large projects.

Example: Cost Calculation

Let’s assume we have a copper alloy part with the following specifications:

- Dimensions: 100mm x 50mm x 10mm

- Complexity: Medium complexity geometry

- Surface Finish: Anodized

- Quantity: 50 pieces

Material Cost

- Price of copper alloy: $10/kg

- Weight per part: 0.4 kg

- Total material cost: 50 pieces x 0.4 kg x $10/kg = $200

Machining Cost

- Machining time for medium complexity parts: 2 hours/part

- Machining rate: $100/hour

- Total machining cost: 50 pieces x 2 hours/piece x $100/hour = $10,000

Surface Finish Cost

- Anodizing cost: $20/piece

- Total surface finish cost: 50 pieces x $20/piece = $1,000

Tool and Equipment Wear

- Copper alloy causes significant tool wear, requiring frequent replacement

- Estimated tool and equipment wear cost: $500

Other Costs

- Quality control and inspection fees: $500

- Packaging and shipping fees: $200

Total cost = Material cost + Machining cost + Surface finish cost + Tool and equipment wear + Other costs

Total cost = $200 + $10,000 + $1,000 + $500 + $700 = $12,400

Cost per part = Total cost / Quantity

Cost per part = $12,400 / 50 pieces = $248/piece

This example provides a rough estimate of the cost. Actual costs will vary based on specific designs, process requirements, and quantities. To receive an accurate quote, please provide detailed mechanical drawings and technical specifications. We will then provide a customized quote based on your needs.

Production Lead Time and Delivery Time

Typical Lead Time from Order Placement to Delivery

At Modo Rapid, our standard lead time from order placement to delivery typically ranges from 1 to 2 weeks. This timeline includes:

- Order Confirmation and Planning: 1-2 days

- Procurement of Materials: 2-3 days

- Machining and Production: 5-7 days

- Quality Control and Inspection: 1-2 days

- Packaging and Shipping: 1-2 days

How Do We Deal with Your Expedited Orders?

Yes, we can shorten the production time for expedited orders. If you require faster delivery, please inform us at the time of order placement. Expedited orders are subject to an additional fee and depend on the current production schedule and the complexity of the parts. By prioritizing your order, we can often reduce the lead time to 1-7 days.

Our team is committed to meeting your deadlines and ensuring that you receive your parts on time, even for urgent projects. Please contact us directly to discuss your specific requirements and expedited options.

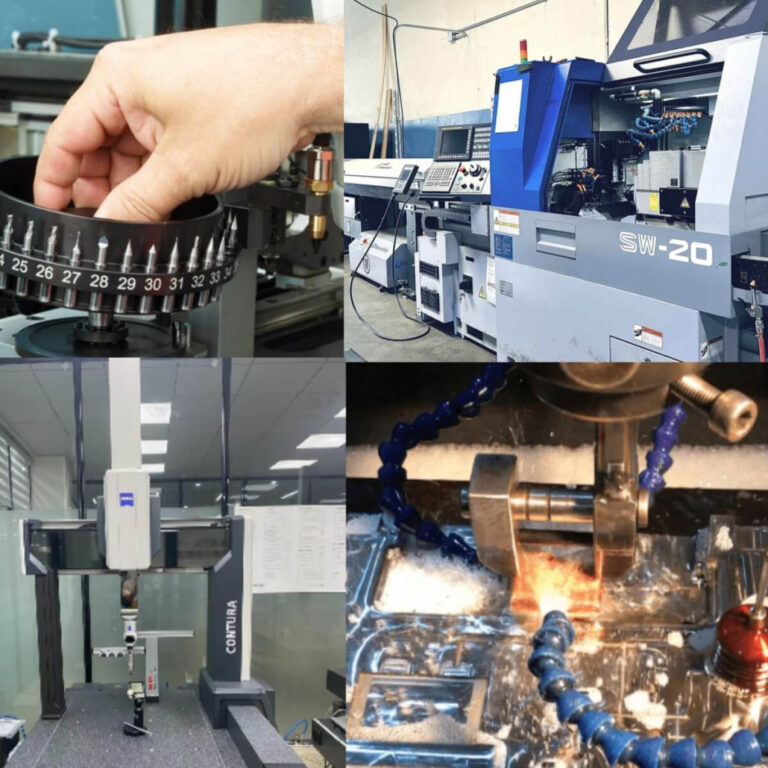

How Do We Ensure Consistency and Quality for Each Batch of Parts?

Quality Control Measures

- Advanced Inspection Tools: Utilization of CMMs (Coordinate Measuring Machines), laser scanners, and precision gauges to measure critical dimensions and geometries.

- In-Process Monitoring: Continuous monitoring during machining processes to detect and correct deviations in real-time.

- Material Verification: Comprehensive material testing, including chemical composition and mechanical property analysis, to ensure conformity with specifications.

- Surface Finish Analysis: Employing profilometers and other surface finish measurement tools to guarantee that all parts meet required surface quality standards.

- Environmental Controls: Maintaining a controlled environment in production areas to minimize the impact of temperature and humidity variations on machining accuracy.

Ensuring Consistency and Quality for Each Batch

- Standard Operating Procedures (SOPs): Strict adherence to standardized processes for each operation to ensure uniformity across all production stages.

- First Article Inspection (FAI): Conducting thorough inspections on the first piece of each batch to verify that it meets all specified requirements before proceeding with full-scale production.

- Statistical Process Control (SPC): Applying SPC techniques to monitor and control the manufacturing process, ensuring that variations are kept within acceptable limits.

- Lot Traceability: Implementing comprehensive traceability systems to track materials and processes for each batch, allowing for easy identification and resolution of any quality issues.

- Final Inspection and Testing: Performing rigorous final inspections and functional tests on all parts before shipment to confirm that they meet client specifications and quality standards.

Our commitment to stringent quality control measures ensures that you receive consistent, high-quality parts in every batch, supporting your projects’ success and reliability.

Why Modo Rapid is Your Trusted Partner for Copper Projects

At Modo Rapid, we combine extensive experience, advanced technology, and a skilled team to deliver high-quality copper parts.

- Rich Experience: Over a decade in copper machining across various industries.

- Advanced CNC Technology: Cutting-edge equipment for precision and efficiency in complex geometries.

- Skilled Team: Expert engineers and technicians dedicated to quality and overcoming copper’s unique challenges.

- Stringent Quality Control: Rigorous measures at every stage ensure consistent, reliable parts.

- Customer-Centric Approach: Tailored solutions with open communication and collaboration.

- Innovative Solutions: Continuous investment in R&D for advanced, competitive solutions.

Client Feedback & Reviews

Ensuring Your Compliance with Environmental and Industry Standards

At Modo Rapid, we prioritize your need for environmentally responsible and industry-compliant manufacturing processes.

Meeting Your Environmental and Industry Standards: Our operations are designed to align with stringent environmental and industry regulations, ensuring that your projects not only meet but exceed these standards.

Certifications That Matter to You:

- ISO 9001: Guaranteeing consistent quality and continuous improvement in every product you receive.

- ISO 14001: Demonstrating our commitment to environmental management, so you can trust our sustainable practices.

- RoHS Compliance: Ensuring our materials are free from hazardous substances for your safety and peace of mind.

- REACH Compliance: Managing chemicals responsibly in our products to meet your regulatory requirements.

- IATF 16949: Meeting the rigorous quality management standards required for the automotive industry, ensuring the highest quality for your automotive projects.

FAQ

Copper materials are a significant category of commercial metals, with various grades available for CNC machining. These grades have different properties and compositions, making them suitable for specific machining projects.

Choosing the right copper material involves considering the specific properties required for your project. Factors such as electrical conductivity, machinability, and strength are critical in determining the best copper grade.

Pure copper is typically soft and malleable, with 0.7% total impurities in commercial grades. It can be alloyed in small volumes to modify its primary properties. Pure copper is ideal for electrical components like wiring and motors and is also used in manufacturing heat exchangers. Its UNS designation numbers range from C10100 to C13000.

Electrolytic copper comes from cathode copper with 99.95% purity, processed through electrolysis. This process involves putting copper compounds into a solution and applying electricity to purify the material. C11000 is a common electrolytic copper grade, known for its high electrical conductivity and ductility, making it perfect for electrical applications such as busbars, windings, wires, and cables.

Oxygen-free copper has the highest purity with little to no oxygen content, making it ideal for electrical components due to its high conductivity. C10100 (Oxygen-Free Electronic) and C10200 (Oxygen-Free) are typical examples. C10100 contains about 0.0005% oxygen and is more expensive, while C10200 contains 0.001% oxygen and offers high electrical conductivity equivalent to electrolytic copper materials.

Oxygen-free copper is made from high-quality cathode copper through induction melting. This process involves melting the cathode under non-oxidizing conditions created by a graphite bath covering, reducing the hydrogen content in the working environment.

Free-machining copper contains various alloying elements like zinc, nickel, phosphorus, and tin, enhancing its machinability. Brass (zinc and copper) and bronze (tin, copper, and phosphorus) are significant constituents, offering excellent workability, corrosion resistance, impact strength, and hardness.

Free-machining copper is well-suited for a wide range of machining applications, including gears, coins, automotive hydraulics, torches, and machined electrical components.

This FAQ aims to provide a clear understanding of the various copper grades used in CNC machining and their specific properties and applications. For more detailed information or to choose the best copper grade for your project, please contact Modo Rapid.

Machining copper is challenging due to its softness and tendency to adhere to cutting tools (galling). Its high thermal conductivity can also lead to heat buildup, causing tool wear and deformation.

Tellurium copper (C14500) is considered the best machinable copper due to its improved machinability while retaining good electrical conductivity.

Copper is generally harder to machine than aluminum due to its tendency to gall and lower thermal conductivity, which can lead to more tool wear and heat management issues.

Grades like C110 (Electrolytic Tough Pitch Copper) and C145 (Tellurium Copper) are commonly used for machining due to their favorable properties.

Milling speeds for copper typically range from 150 to 300 meters per minute, depending on the specific alloy and tooling used.

No, cast iron is generally stronger and harder than copper, making it more suitable for applications requiring high strength and wear resistance.

- Pure Copper (e.g., C10100, C11000)

- Oxygen-Free Copper (e.g., C10100, C10200)

- Free-Machining Copper (e.g., C14500)

Type M copper, with its thinner wall, is suitable for low-pressure residential applications but not recommended for heavy-duty or high-pressure uses.

Free-machining copper contains alloying elements like tellurium or sulfur, which enhance its machinability. C14500 is a common example.

For machining copper, 2 to 3 flutes are typically recommended to allow for efficient chip removal and prevent clogging.

A 2 flute end mill has better chip clearance and is ideal for softer materials, while a 4 flute end mill provides a better finish and is suitable for harder materials.

Copper is durable and has a long lifespan, making it ideal for high-temperature and high-pressure applications. PEX is easier to install, flexible, and cost-effective for residential plumbing.

Type K copper has the thickest walls among copper pipes, making it suitable for high-pressure applications and underground installations.

Custom Copper Parts for Your Project!

Experience tailored excellence with our high-precision copper parts. We manufacture to your exact specifications, ensuring top-quality results and cost efficiency.

At Modo Rapid, we prioritize your project’s success, offering unmatched precision and competitive prices. Choose us for seamless, customized copper part solutions. Send us your specifications and let us help you achieve your goals.

Get a quote for custom copper parts