CNC Plastic

- Superior Corrosion and Fatigue Resistance: Perfect for aerospace, medical, and other demanding industries.

- Precision:0.05mm

- Fast Turnaround Times: Receive your parts in just 1-7 days

- Certified Quality: ISO9001:2015 and IATF16949 certified processes for top-quality results.

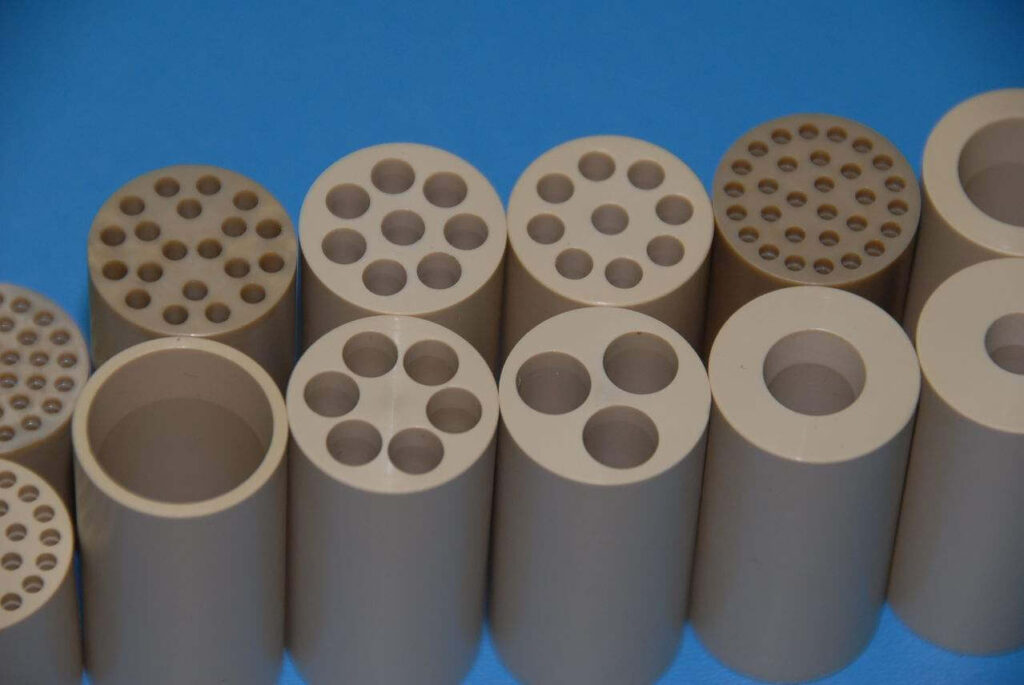

Custom Plastic CNC Parts

CNC machined plastic parts are critical in various sectors, from aerospace to healthcare. Modo Rapid offers an extensive selection of plastics for on-demand custom manufacturing. Click on each category to explore specific materials and their properties in detail.

Common Plastic Materials

ABS (Acrylonitrile Butadiene Styrene)

- Standard ABS: Known for its toughness and impact resistance, suitable for a wide range of applications.

- Flame-Retardant ABS: Enhanced fire resistance, ideal for electrical and automotive components.

- High-Impact ABS: Provides superior impact strength, used in protective gear and automotive parts.

- Medical Grade ABS: Biocompatible and meets medical industry standards, suitable for medical devices and equipment.

- Weather-Resistant ABS: Offers UV stability and resistance to outdoor elements, used in outdoor applications and enclosures.

CNC Machining PEEK

- Standard PEEK: Excellent mechanical strength and chemical resistance, suitable for a variety of applications.

- High-Temperature PEEK: Maintains performance in extreme temperatures, ideal for aerospace and industrial applications.

- Reinforced PEEK: Enhanced with glass or carbon fibers for increased strength and stiffness, used in high-load applications.

- Medical Grade PEEK: Biocompatible and meets medical industry standards, suitable for implants and surgical instruments.

- Wear-Resistant PEEK: Optimized for low friction and wear, used in bearings, bushings, and gears.

- Standard Nylon: Excellent toughness and wear resistance for general use.

- Glass-Filled Nylon: Enhanced strength and rigidity for load-bearing applications.

- Carbon-Filled Nylon: Superior stiffness and thermal conductivity for high-performance parts.

- Oil-Filled Nylon: Reduced friction and improved wear resistance for sliding applications.

- Flame-Retardant Nylon: Enhanced safety for electrical and electronic components.

CNC Machining POM

- Standard POM: Known for its toughness and impact resistance, suitable for general-purpose applications.

- POM-C (Copolymer): Offers better chemical resistance and stability.

- POM-H (Homopolymer): Provides higher mechanical strength and stiffness.

- Glass-Filled POM: Enhanced rigidity and dimensional stability.

- UV-Stabilized POM: Ideal for outdoor applications requiring UV resistance.

- Standard HDPE: Known for its toughness and impact resistance, suitable for general-purpose applications.

- UV-Stabilized HDPE: Offers UV stability and resistance to outdoor elements, used in outdoor applications and enclosures.

- High-Molecular-Weight HDPE: Provides better wear resistance and higher impact strength.

- Antistatic HDPE: Reduces static electricity buildup, ideal for electronic applications.

- FDA Compliant HDPE: Safe for food contact applications.

Comprehensive List of Plastic Part Finishes

Glossy Finish (Grade A)

- Description: High-gloss, mirror-like surface that is highly reflective.

- Applications: Ideal for consumer products requiring a luxurious and aesthetically pleasing appearance, such as automotive interiors, electronics, and cosmetic packaging.

Semi-Gloss Finish (Grade B)

- Description: Offers a moderate shine, balancing between high-gloss and matte finishes. It provides a smooth appearance while hiding minor surface imperfections.

- Applications: Used for products that require an attractive yet functional finish, like household appliances and automotive components.

Matte Finish (Grade C)

- Description: Non-reflective, dull surface that provides a soft, velvety appearance. It’s effective at hiding imperfections and is less likely to show fingerprints.

- Applications: Commonly used for internal parts or products where a subdued appearance is desired.

Textured Finish (Grade D)

- Description: Involves creating a specific pattern or texture on the plastic surface, such as grains or bumps, which can enhance grip or provide a particular aesthetic.

- Applications: Ideal for parts where grip is important, like handles, or for products that require a unique tactile experience.

Dull Finish

- Description: The roughest and least polished surface, often achieved through sandblasting. It lacks reflectivity and is typically used where aesthetics are not a priority.

- Applications: Suitable for internal components or where functionality takes precedence over appearance.

Specialty Finishes

- Anodizing: Adds a durable and corrosion-resistant oxide layer, often used for parts exposed to harsh environments.

- Electroplating: Applies a thin metal layer to the plastic surface for enhanced aesthetics and durability, commonly used in decorative applications.

- Anti-Slip Coatings: These finishes improve grip and are often applied to handles or surfaces requiring secure handling.

CNC Plastic Machining Services

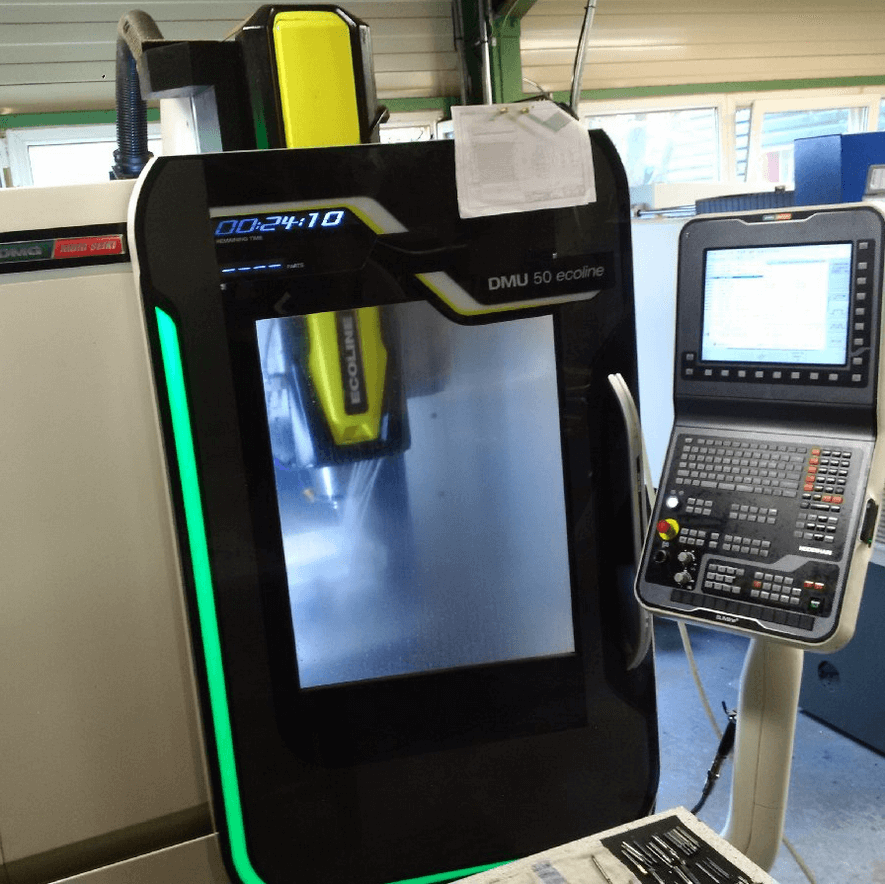

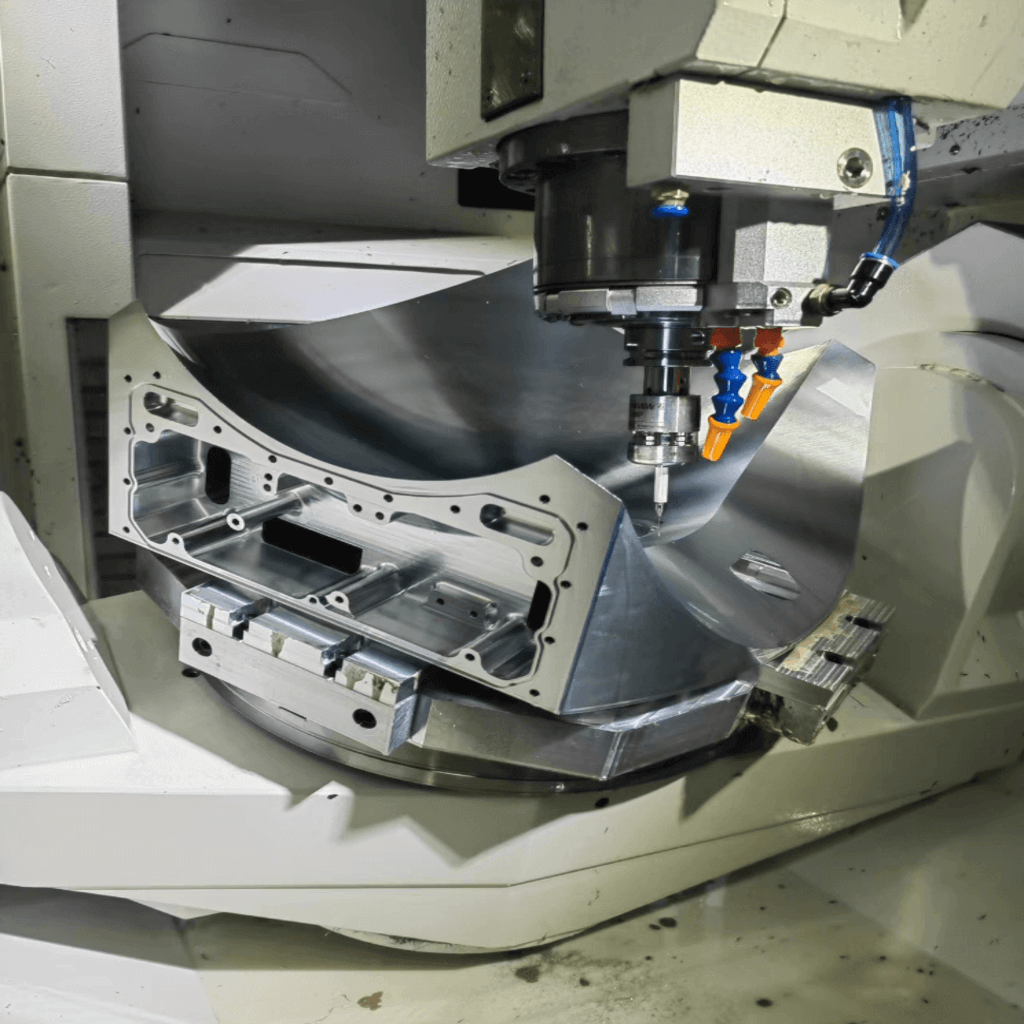

CNC plastic machining transforms raw plastic materials into precise components through advanced CNC machinery. At Modo Rapid, our skilled machinists use 3- and 5-axis CNC machines to produce high-quality plastic parts, ensuring tight tolerances and exceptional surface finishes.

Delivery Time

Our commitment to on-time delivery is critical to your project’s success. We offer expedited services for prototypes:

- 1-30 pieces: Delivery within 7 days

- 31-100 pieces: Delivery within 15 days

- 100-5000 pieces: Delivery within 18 days

Urgent orders can be reprioritized based on your needs.

Cost Control

We understand that cost efficiency is crucial when sourcing CNC prototypes. Our competitive pricing ensures that you get the best value without compromising on quality. Here’s how we keep costs low:

- Processing Fees: By utilizing advanced CNC machinery, we reduce production time and costs. For instance, our 5-axis milling can complete complex parts in fewer setups, saving both time and money.

- Material Costs: We have established relationships with top material suppliers, allowing us to procure high-quality materials at discounted rates. For example, our bulk purchasing of aluminum alloys translates to significant savings for our clients.

- Shipping Fees: Our strategic partnerships with leading logistics companies ensure efficient and cost-effective shipping. For instance, our expedited shipping options for urgent orders do not come with the high price tag you’d expect.

By choosing us, you’re guaranteed low-cost, high-quality CNC prototypes that meet your budget and performance requirements. For example, a recent project involving 50 custom parts was delivered within budget and ahead of schedule, demonstrating our commitment to cost efficiency and timely delivery.

Communication Efficiency

Effective communication is key. We are online 16 hours daily, providing swift, expert support globally, ensuring seamless project management.

Flexibility

We specialize in prototypes and small batches, accommodating even single orders with flexible production and payment options.

Confidentiality

We sign NDAs before discussing design details. Production occurs in temperature-controlled, sealed facilities.

Our employees and the company are also bound by confidentiality and non-compete agreements. The company and its employees are in a stable relationship to ensure that your designs are safe

What are the maximum part sizes and complex geometries you can handle?

- Part Sizes: We can machine parts with maximum dimensions of 1800mm x 800mm x 600mm, meeting the needs of most industrial applications.

- Complex Geometries: Our 5-axis and 4-axis CNC machining centers can precisely machine complex geometries, including internal channels, intricate surfaces, and high-precision apertures. Our equipment can manage fine features and tight tolerances, ensuring your design intentions are perfectly realized.

What advanced CNC equipment do you have for machining plastics?

- 5-Axis CNC Machining Centers: Capable of producing complex geometries and intricate designs, ensuring high accuracy and smooth finishes on brass components.

- High-Speed CNC Mills: Equipped with robust spindles and high feed rates, ideal for efficiently machining brass while maintaining tight tolerances.

- Multi-Tasking CNC Lathes: These machines combine milling and turning capabilities, allowing for versatile and efficient production of brass parts in a single setup.

- Precision CNC Grinders: Essential for achieving the fine surface finishes and exact dimensions required for high-performance brass components.

- EDM (Electrical Discharge Machining): Utilized for cutting intricate shapes and hard-to-machine areas, providing high precision without inducing stress in the brass material.

- Mill-turn machine: Combines turning and milling functions in one, completing complex multi-axis machining on a single setup. It improves accuracy and efficiency, ideal for high-precision parts. For brass alloy parts, its high rigidity and multi-axis capabilities reduce machining time and ensure quality. Using efficient tools and optimized parameters further enhances production speed and reliability.

How Do We Deal With Your Expedited Orders?

Yes, we can shorten the production time for expedited orders. If you require faster delivery, please inform us at the time of order placement.

Expedited orders are subject to an additional fee and depend on the current production schedule and the complexity of the parts. By prioritizing your order, we can often reduce the lead time to 1-7 days.

Our team is committed to meeting your deadlines and ensuring that you receive your parts on time, even for urgent projects. Please contact us directly to discuss your specific requirements and expedited options.

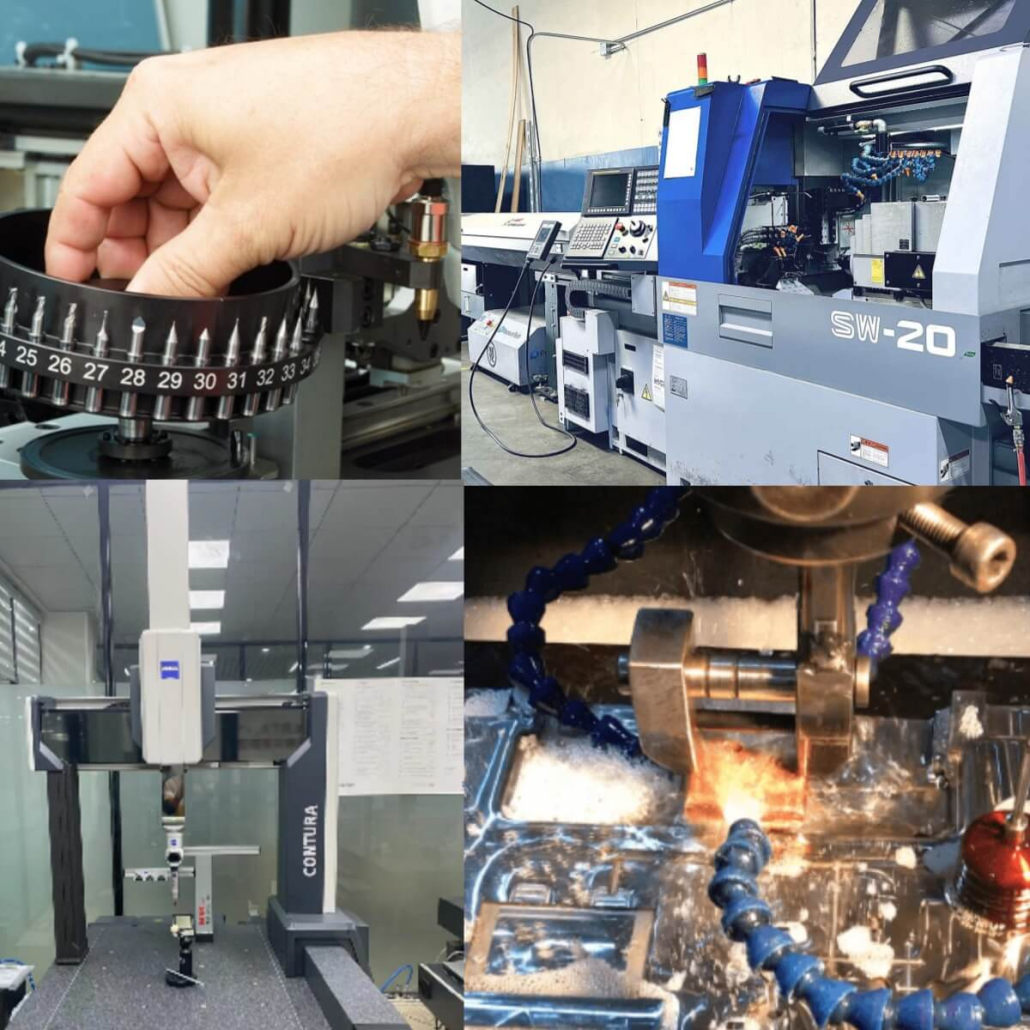

How Do We Ensure Consistency and Quality for Each Batch of Parts?

Quality Control Measures:

Advanced Inspection Tools: Utilization of CMMs (Coordinate Measuring Machines), laser scanners, and precision gauges to measure critical dimensions and geometries.

In-Process Monitoring: Continuous monitoring during machining processes to detect and correct deviations in real-time.

Material Verification: Comprehensive material testing, including chemical composition and mechanical property analysis, to ensure conformity with specifications.

Surface Finish Analysis: Employing profilometers and other surface finish measurement tools to guarantee that all parts meet required surface quality standards.

Environmental Controls: Maintaining a controlled environment in production areas to minimize the impact of temperature and humidity variations on machining accuracy.

Ensuring Consistency and Quality for Each Batch:

Standard Operating Procedures (SOPs): Strict adherence to standardized processes for each operation to ensure uniformity across all production stages.

First Article Inspection (FAI): Conducting thorough inspections on the first piece of each batch to verify that it meets all specified requirements before proceeding with full-scale production.

Statistical Process Control (SPC): Applying SPC techniques to monitor and control the manufacturing process, ensuring that variations are kept within acceptable limits.

Lot Traceability: Implementing comprehensive traceability systems to track materials and processes for each batch, allowing for easy identification and resolution of any quality issues.

Final Inspection and Testing: Performing rigorous final inspections and functional tests on all parts before shipment to confirm that they meet client specifications and quality standards.

Our commitment to stringent quality control measures ensures that you receive consistent, high-quality parts in every batch, supporting your projects’ success and reliability.

Ensuring Your Compliance with Environmental and Industry Standards

At Modo Rapid, we prioritize your need for environmentally responsible and industry-compliant manufacturing processes.

Meeting Your Environmental and Industry Standards: Our operations are designed to align with stringent environmental and industry regulations, ensuring that your projects not only meet but exceed these standards.

Certifications That Matter to You:

- ISO 9001: Guaranteeing consistent quality and continuous improvement in every product you receive.

- ISO 14001: Demonstrating our commitment to environmental management, so you can trust our sustainable practices.

- RoHS Compliance: Ensuring our materials are free from hazardous substances for your safety and peace of mind.

- REACH Compliance: Managing chemicals responsibly in our products to meet your regulatory requirements.

- IATF 16949: Meeting the rigorous quality management standards required for the automotive industry, ensuring the highest quality for your automotive projects.

FAQ

We can achieve tight tolerances up to ±0.05mm, depending on the material and specific part requirements.

Yes, we provide rapid prototyping services to help you validate your designs before full-scale production.

Yes, our advanced 3- and 5-axis CNC machines are capable of producing highly intricate and detailed components with exceptional precision.

We accept various design file formats (such as STEP, IGES, and STL) and ensure strict confidentiality and security of your proprietary designs.

Yes, we can provide material certifications, inspection reports, and other necessary documentation upon request.

We offer global shipping and work with reliable logistics partners to ensure timely and safe delivery of your parts. Shipping options and costs will be detailed in the quotation.

Quality control is crucial, typically involving rigorous inspection processes, adherence to ISO standards, and advanced quality assurance techniques. Buyers often inquire about the supplier’s quality certifications and their processes for maintaining consistent part quality

Problems such as inconsistent part dimensions or poor surface finishes can arise from equipment wear, improper tooling, or inadequate process controls. It’s essential for suppliers to have protocols in place to address and prevent these issues

Lead times can vary based on the complexity of the parts, the materials used, and the supplier’s current workload. Procurement teams often ask about typical lead times and how suppliers manage to meet delivery deadlines

Post-sale support, including warranty services, repair options, and ongoing customer support, is an important consideration. Buyers want assurance that they can rely on the supplier for assistance even after the purchase is complete

Modo Rapid’s CNC plastic machines are distinguished by their precision and versatility. With high-quality CNC lathe tool holders and mill cutting tools, our machines deliver accurate cuts even on complex designs. Built with durable, heavy-duty materials, our machines are ideal for industrial and commercial applications, operating efficiently at high speeds.

Yes, Modo Rapid can incorporate various features into your plastic parts, such as threads, holes, and slots. Our CNC machines are fully equipped to produce parts with intricate designs and precise tolerances, customized to your specifications.