CNC Prototypes

- Machined Metal and Plastic Prototypes & Production Parts in as Fast as 1-7 Days.

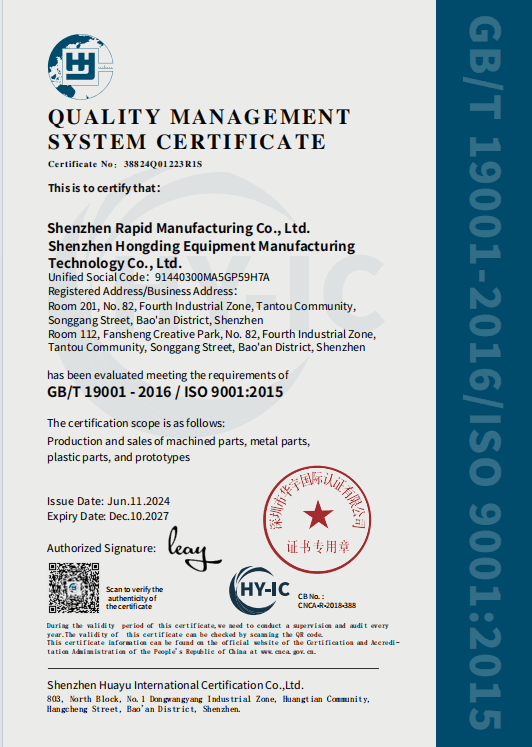

- ISO 9001 & IATF 16949

- 100% Factory Price

Our Technical Capabilities

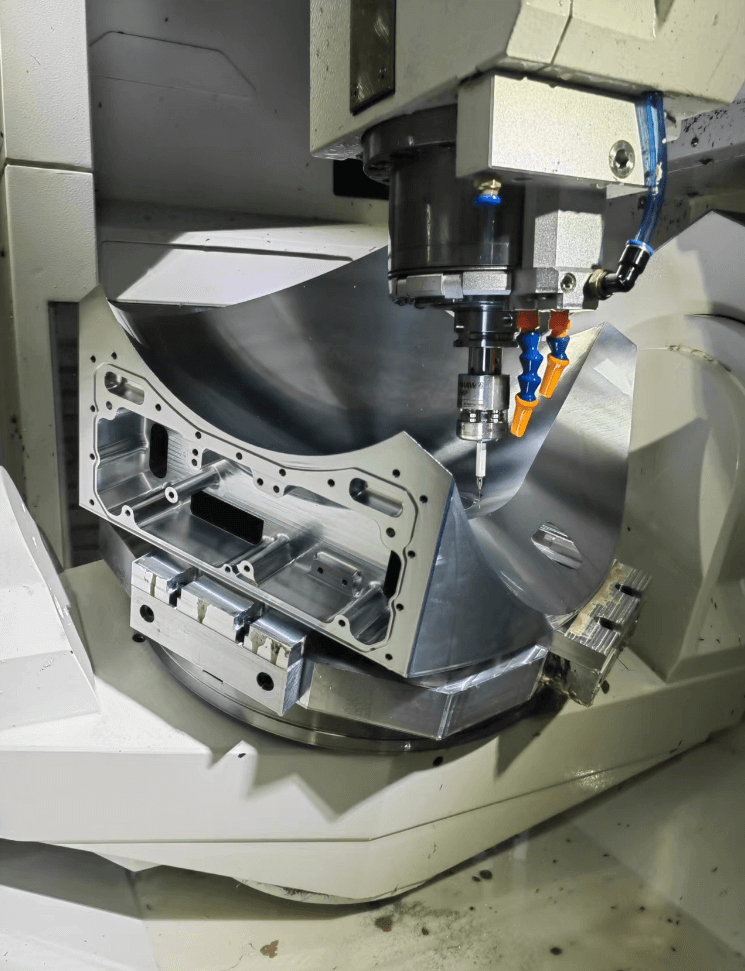

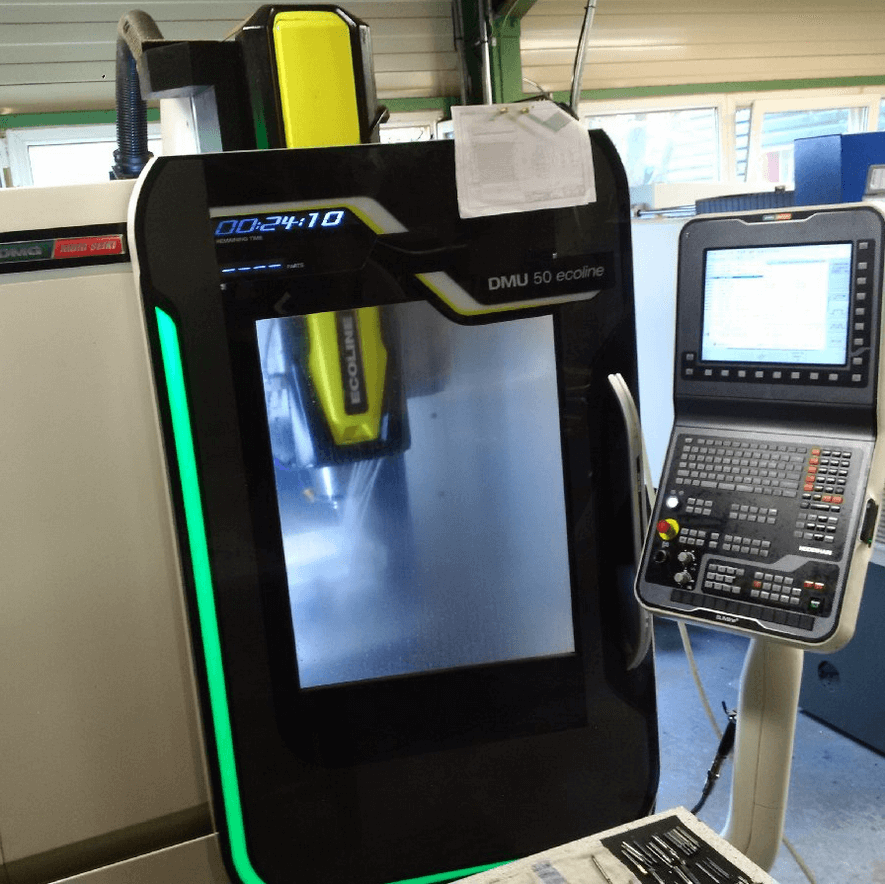

CNC Milling

CNC milling machines excel at handling geometric designs and meeting rapid production needs. Our CNC prototyping services feature both 3-axis and 5-axis milling capabilities.

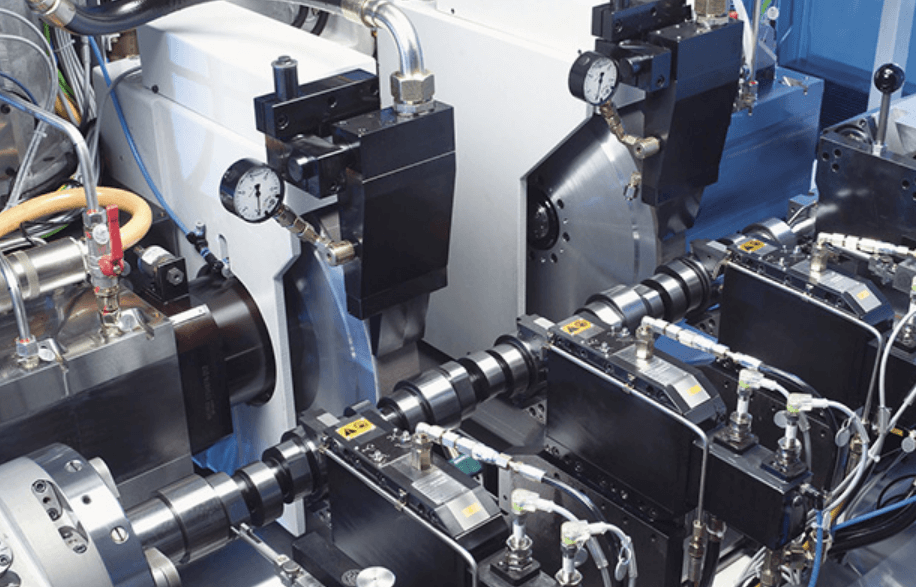

CNC Turning

CNC turning involves using an automated lathe to shape a rotating workpiece. This process is ideal for creating rounded or cylindrical geometries.

CNC Drilling

CNC drilling is a process in which an automated machine creates precise holes in a workpiece. Drilling is essential for achieving accurate and consistent hole patterns in various materials.

CNC Grinding

CNC grinding is a process in which a computer-controlled grinding wheel removes material from a workpiece. Grinding is useful for achieving high precision and smooth surface finishes on both flat and cylindrical geometries.

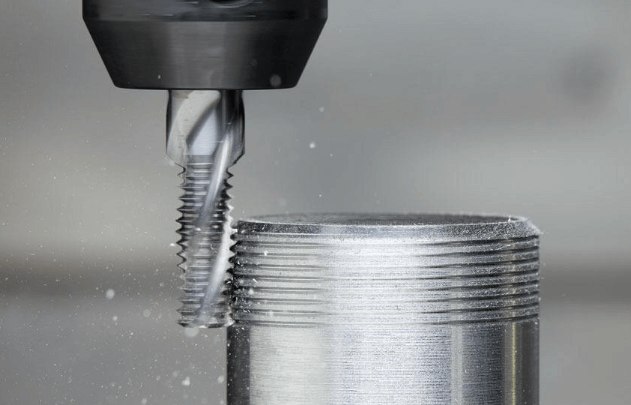

CNC Threading

CNC threading is a process in which an automated machine precisely cuts threads into a workpiece. Threading is essential for creating screw threads and is useful for components that require fastening capabilities.

Work with A Certified Company

CNC Milling Design Advice and Capabilities

| 3-Axis Milling | 5-Axis Milling | Turning | |

|---|---|---|---|

| Max. Part size | 1800 x 950 x 480 mm (66.9 x 37.4 x 18.9 in) | 950 x 850 x 570 mm (37.4 x 33.5 x 22.4 in) | Ø 800 x 2000 mm (Ø 31.5 x 23.6 in) |

| Min. Part size | 12 x 12 x 12 mm (0.47 x 0.47 x 0.47 in) | 12 x 12 x 12 mm (0.47 x 0.47 x 0.47 in) | 6 x 6 x 6 mm (0.24 x 0.24 x 0.24 in) |

| Min. Feature size | Ø 0.8 mm (Ø 0.031 in) | Ø 0.8 mm (Ø 0.031 in) | Ø 0.8 mm (Ø 0.031 in) |

| Standard tolerance | Metals: +/- 0.10 mm (+/- 0.004 in) | Metals: +/- 0.10 mm (+/- 0.004 in) | Metals: +/- 0.10 mm (+/- 0.004 in) |

| Plastics: +/- 0.15 mm (+/- 0.006 in) | Plastics: +/- 0.15 mm (+/- 0.006 in) | Plastics: +/- 0.15 mm (+/- 0.006 in) | |

| Lead time | As low as 7 days for fewer than 50 parts | As low as 9 days for fewer than 50 parts | As low as 7 days for fewer than 50 parts |

CNC Machining Materials

| Material Type | Examples |

|---|---|

| Metals | Aluminum (6061, 7075, 2024, 5052) |

| Stainless Steel (304, 316, 17-4 PH) | |

| Steel (A36, 1018, 1045, 4140) | |

| Brass (C360) | |

| Copper (C110, C101) | |

| Titanium (Grade 2, Grade 5) | |

| Magnesium | |

| Nickel Alloys (Inconel, Monel) | |

| Tool Steel (D2, O1, A2) | |

| Plastics | ABS |

| Nylon (PA6, PA66) | |

| Polycarbonate (PC) | |

| Polyethylene (PE) | |

| Polypropylene (PP) | |

| PEEK | |

| PTFE (Teflon) | |

| PVC | |

| Delrin (POM) | |

| Acrylic (PMMA) | |

| Composites | Carbon Fiber |

| Fiberglass | |

| Specialty Materials | Ceramics (Alumina, Zirconia) |

| Graphite | |

| G10 | |

| Phenolic | |

| Other Materials | Wood (various types) |

| Foam |

Customize Your CNC Prototype Parts According to Drawings

At Modo Rapid, we specialize in manufacturing high-precision CNC prototype parts tailored to your specific designs. Our state-of-the-art 5-axis CNC machines enable us to produce complex and intricate components with unparalleled precision. To ensure the highest quality, we utilize ZEISS Coordinate Measuring Machines (CMM) for rigorous inspection and verification.

As a leading factory in Shenzhen, we understand the critical importance of accuracy and quality in your projects. Partner with us for precision, efficiency, and the expertise you need to bring your prototypes to life.

| Post-Processing Techniques |

|---|

| Anodizing, Bead Blasting, Black Oxide, Brushing |

| Chromate Conversion Coating, Deburring, Electropolishing, Heat Treatment |

| Laser Engraving, Painting, Passivation, Plating (Nickel, Chrome, Zinc) |

| Polishing, Powder Coating, Sandblasting, Shot Peening |

| Tumbling, Ultrasonic Cleaning, Vibratory Finishing, Welding |

Quality Checks at Every Stage for Your Parts

Initial Material Inspection:

Equipment: Optical Emission Spectrometer (OES) or X-ray Fluorescence (XRF) Analyzer. Purpose: Verify the composition and quality of raw materials before production begins.

In-Process Dimensional Inspection:

Equipment: Coordinate Measuring Machine (CMM) and Vernier Calipers. Purpose: Ensure parts meet dimensional specifications during various stages of machining.

Surface Finish Inspection:

Equipment: Surface Roughness Tester. Purpose: Check the surface texture and finish to meet the required standards.

Final Quality Inspection:

Equipment: ZEISS Coordinate Measuring Machine (CMM) and Optical Comparator. Purpose: Conduct a comprehensive inspection of the finished part to verify all dimensions, tolerances, and overall quality.

2 ZEISS CMMs for your project 24/7

We are a 24-hour facility with technicians working 3 shifts. For many of our customer’s urgent projects, we use our 2 ZEISS CMM’s to inspect the parts and make sure your project goes smoothly.

Quality Inspections We Perform for Your Parts

Delivery Time

When selecting a supplier, it’s crucial to consider their production cycle and delivery capabilities, especially for urgent projects. Our commitment to timely delivery is unwavering, ensuring your project stays on track.

For prototypes, we offer the following delivery times:

- 1-30 pieces: Delivery within 7 days

- 31-100 pieces: Delivery within 15 days

- 100-500 pieces: Delivery within 18 days

We can reprioritize orders in case of project emergencies. Please let us know in advance.

Cost Control

We understand that cost efficiency is crucial when sourcing CNC prototypes. Our competitive pricing ensures that you get the best value without compromising on quality. Here’s how we keep costs low:

- Processing Fees: By utilizing advanced CNC machinery, we reduce production time and costs. For instance, our 5-axis milling can complete complex parts in fewer setups, saving both time and money.

- Material Costs: We have established relationships with top material suppliers, allowing us to procure high-quality materials at discounted rates. For example, our bulk purchasing of aluminum alloys translates to significant savings for our clients.

- Shipping Fees: Our strategic partnerships with leading logistics companies ensure efficient and cost-effective shipping. For instance, our expedited shipping options for urgent orders do not come with the high price tag you’d expect.

By choosing us, you’re guaranteed low-cost, high-quality CNC prototypes that meet your budget and performance requirements. For example, a recent project involving 50 custom parts was delivered within budget and ahead of schedule, demonstrating our commitment to cost efficiency and timely delivery.

Communication Efficiency

Effective communication is key. We are online 16 hours daily, providing swift, expert support globally, ensuring seamless project management.

Flexibility

We specialize in prototypes and small batches, accommodating even single orders with flexible production and payment options.

Confidentiality

We sign NDAs before discussing design details. Production occurs in temperature-controlled, sealed facilities.

Our employees and the company are also bound by confidentiality and non-compete agreements. The company and its employees are in a stable relationship to ensure that your designs are safe

Custom CNC Parts for Every Industry

Precision-engineered solutions tailored to meet the unique demands of automotive, aerospace, medical, and more industries, ensuring superior performance and reliability.

Frequently Ask Questions

We have a rigorous quality control process, including:

- Use of advanced CMM machines for precise measurement.

- Strict adherence to ISO 9001 and IATF 16949 standards.

- Continuous in-process inspections and final quality checks. Our production environment is temperature-controlled and sealed to maintain optimal conditions.

Yes, we specialize in prototyping and small batch production. We are highly flexible and can accommodate orders as small as a single prototype, ensuring the same level of quality and attention to detail as larger orders.

We prioritize the confidentiality of your designs and project information. We sign Non-Disclosure Agreements (NDAs) before discussing any design details. Our entire production process takes place in temperature-controlled, sealed facilities to ensure maximum security and confidentiality.

We have established partnerships with leading logistics companies to ensure efficient and cost-effective shipping. We provide expedited shipping options for urgent orders and handle all customs documentation to facilitate smooth international deliveries.

Yes, our engineering and project teams are available to provide comprehensive technical support and consultation. From initial design review to final production, we guide you through each step to ensure your project’s success.

For urgent orders, we prioritize production schedules and utilize expedited shipping services to meet tight deadlines. Our flexible production capabilities allow us to quickly adapt to your needs and ensure timely delivery without compromising quality.