Digital Light Synthesis (DLS)

Table of Contents

Digital Light Synthesis (DLS) Tolerances Overview

| Feature | Standard Resolution | High Resolution |

|---|---|---|

| Build Envelope | 400 x 300 x 200 mm (15.75″ x 11.81″ x 7.87″) | 200 x 200 x 100 mm (7.87″ x 7.87″ x 3.94″) |

| Layer Height | 25-100 μm | 25-50 μm |

| XY Plane Tolerance | +/- 0.1% with a minimum of +/- 0.1 mm | +/- 0.05% with a minimum of +/- 0.05 mm |

| Z Plane Tolerance | +/- 0.1% with a minimum of +/- 0.1 mm | +/- 0.05% with a minimum of +/- 0.05 mm |

| Minimum Linear Feature Size | 0.1 mm (0.0039”) | 0.05 mm (0.00197”) |

| Minimum Radial Feature Size | 0.1 mm (0.0039”) | 0.05 mm (0.00197”) |

Note: These tolerances are standard for DLS processes and can vary depending on the material, geometry, and machine setup. For more precise tolerances, a manual quote review might be necessary after successful prototype completion. General tolerances apply before any secondary finishing or post-processing unless specified otherwise.

Modo Rapid offers seamless access to premium 3D printing services, utilizing cutting-edge additive manufacturing technologies.

Choose from over 40 materials and 11 finishing options to perfectly match the requirements of any project.

DLS Materials and Their Properties

Modo Rapid offers a wide selection of DLS materials designed for specific applications. Here’s an overview of available materials and their key characteristics:

| Material Name | Description | Tensile Strength (MPa) | Elongation at Break (%) | Flexural Modulus (MPa) |

|---|---|---|---|---|

| RPU 70 | Rigid polyurethane, durable | 35 MPa | 170% | 1000 MPa |

| EPX 82 | Epoxy, high strength | 85 MPa | 7% | 2800 MPa |

| EPU 40 | Elastomeric polyurethane, flexible | 6 MPa | 300% | 20 MPa |

| CE 221 | Cyanate ester, heat-resistant | 50 MPa | 3% | 2000 MPa |

| UMA 90 | Urethane methacrylate, tough | 68 MPa | 11% | 1500 MPa |

Modo Rapid provides these materials for various industrial and commercial applications, ensuring you have the right material for your specific project needs

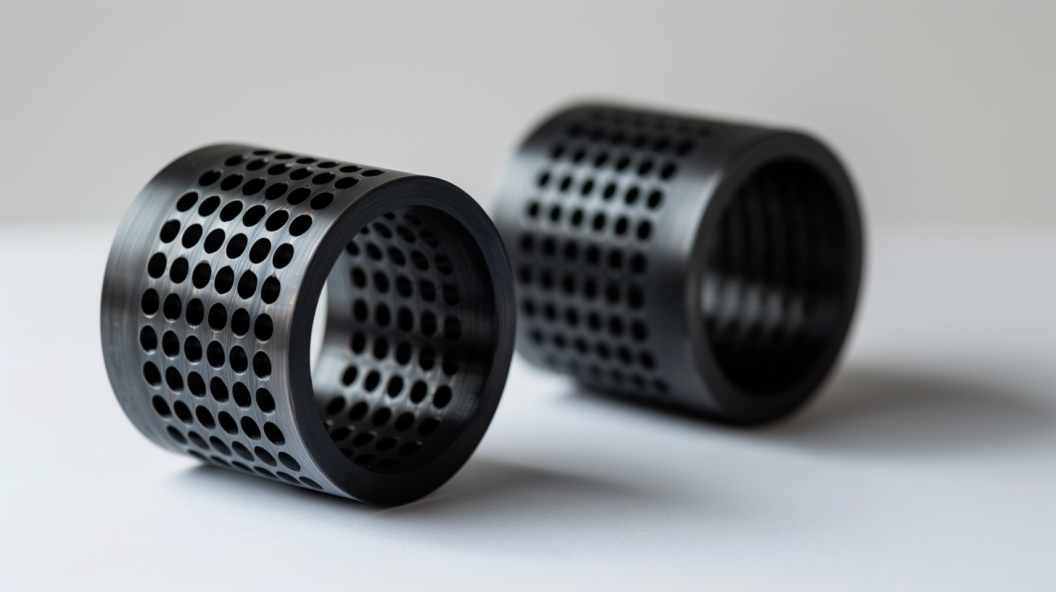

Capabilities of DLS 3D Printers

DLS 3D printing offers high throughput and accuracy, making it ideal for producing end-use parts and complex geometries. Below are the capabilities of our DLS printers:

| Maximum Build Volume | Typical Lead Time | Dimensional Precision | Layer Thickness | Smallest Feature Size | |

|---|---|---|---|---|---|

| Standard DLS | 400 x 300 x 200 mm (15.75″ x 11.81″ x 7.87″) | From 2 business days | ± 0.1% with a minimum of ± 0.1 mm | 25-100 μm | 0.1 mm |

| High-Resolution DLS | 200 x 200 x 100 mm (7.87″ x 7.87″ x 3.94″) | From 2 business days | ± 0.05% with a minimum of ± 0.05 mm | 25-50 μm | 0.05 mm |

Advanced 3D Printing Solutions for Engineering with DLS

Unlock precision-engineered components at every stage of your product development with DLS technology.

- Optimize Material Performance: Utilize advanced resin profiles tailored for your specific application.

- Enhance Resolution: Fine-tune layer height settings for the ideal balance of detail and efficiency.

- Improve Surface Quality: Apply customized post-processing techniques to achieve superior finishes.

DLS Post-Processing

At Modo Rapid, we ensure that all DLS parts are meticulously finished. Support structures are removed, and surfaces are smoothed to meet the highest standards. Transparent parts can be polished to achieve optical clarity, while all parts undergo a final curing process to ensure optimal material properties.

Comparison of 3D Printing Technologies

| Technology | Materials | Price | Dimensional Accuracy | Strengths | Build Volume | Layer Thickness | Min. Feature Size |

|---|---|---|---|---|---|---|---|

| FDM | 5 | $ | ± 0.5% with a lower limit of ± 0.5 mm | Low cost, wide range of materials | 500 x 500 x 500 mm (19.68″ x 19.68″ x 19.68″) | 100-300μm | 2.0 mm (0.0787”) |

| Industrial FDM | 6 | $$$$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012″) | High repeatability, engineering-grade materials | 406 x 355 x 406 mm (15.98” x 13.97” x 15.98″) | 100-330μm | 2.0 mm (0.0787”) |

| Prototyping SLA | 8 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012″) | Smooth surface finish, fine detail resolution | 145 × 145 × 175 mm (5.7″ x 5.7″ x 6.8″) | 50-100μm | 0.2 mm (0.00787”) |

| Industrial SLA | 3 | $$$ | ± 0.2% with a lower limit of ± 0.13 mm (± 0.005″) | Smooth surface finish, large build area | 500 x 500 x 500 mm (19.68″ x 19.68″ x 19.68″) | 50-100μm | 0.2 mm (0.00787”) |

| SLS | 2 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012”) | Design flexibility, no supports required | 395 x 500 x 395 mm (15.53″ x 19.68″ x 15.53″) | 100μm | 0.5 mm (0.0196”) |

| MJF | 2 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (0.012”) | Design flexibility, no supports required | 380 x 285 x 380 mm (14.9” x 11.2” x 14.9”) | 80μm | 0.5 mm (0.0196”) |

Our Commitment to High Standards in DLS 3D Printing

At Modo Rapid, we ensure that every part produced through Digital Light Synthesis (DLS) adheres to the highest manufacturing standards. Our rigorous quality control process ensures that all parts meet precise specifications, with comprehensive inspection reports included with every order.

Parts undergo complete curing according to the resin manufacturer’s guidelines, ensuring optimal material properties before shipping.

Any cavities or hollow sections are thoroughly drained to prevent material build-up and ensure structural integrity.

Support structures are expertly removed, and any residual marks are carefully finished to maintain a smooth surface.

Pros & Cons of 3D Printing with DLS

DLS 3D printing excels in producing parts with remarkable detail, accuracy, and surface quality. The technology supports a wide range of high-performance materials, making it suitable for both prototyping and end-use applications. DLS is particularly advantageous for creating durable, isotropic parts with consistent mechanical properties throughout the entire build.

However, DLS does have some limitations. The initial setup and material costs can be higher compared to other 3D printing technologies. Additionally, while DLS parts are generally durable, they may require post-processing to achieve the desired surface finish and to remove any support structures, which can add time and complexity to the production process.

Design Guidelines for DLS 3D Printing

To achieve optimal results with DLS 3D printing, it’s important to follow specific design guidelines. The table below outlines the recommended sizes for common features in DLS-printed parts. For unsupported walls, a thickness of at least 0.4 mm (0.0157 in) is recommended, while supported walls can be as thin as 0.3 mm (0.0118 in). The minimum feature size for accurate printing is 0.1 mm (0.0039 in), and holes should have a minimum diameter of 0.5 mm (0.0197 in). For escape holes, a minimum diameter of 2.0 mm (0.0787 in) is advised.

1 Free Sample for First-Time Customers

Getting free samples is the best way to inspect suppliers

Production Feasibility Analysis

Before moving into full production, we conduct a comprehensive feasibility analysis to ensure that your design can be efficiently manufactured at scale. This step involves evaluating the materials, manufacturing processes, and potential challenges to ensure a smooth transition from prototype to production. Our team will collaborate closely with you to refine your design, optimize for manufacturability, and mitigate risks.

Before moving into full production, we conduct a comprehensive feasibility analysis to ensure that your design can be efficiently manufactured at scale. This step involves evaluating the materials, manufacturing processes, and potential challenges to ensure a smooth transition from prototype to production. Our team will collaborate closely with you to refine your design, optimize for manufacturability, and mitigate risks.

3D printing

Our 3D printing services offer rapid prototyping with precision and flexibility, allowing you to quickly test and iterate on your designs. We provide a range of 3D printing technologies, including SLA, SLS, and FDM, to match your specific needs, whether you require detailed models or functional parts. This stage is crucial for validating design concepts before moving to more advanced manufacturing processes.

Our 3D printing services offer rapid prototyping with precision and flexibility, allowing you to quickly test and iterate on your designs. We provide a range of 3D printing technologies, including SLA, SLS, and FDM, to match your specific needs, whether you require detailed models or functional parts. This stage is crucial for validating design concepts before moving to more advanced manufacturing processes.

Urethane Casting

For low to medium volume production, urethane casting offers a cost-effective solution with high fidelity to the original prototype. This process is ideal for creating durable, flexible parts that closely resemble injection-molded components. We use high-quality silicone molds and urethane resins to produce parts with excellent surface finishes and physical properties.

For low to medium volume production, urethane casting offers a cost-effective solution with high fidelity to the original prototype. This process is ideal for creating durable, flexible parts that closely resemble injection-molded components. We use high-quality silicone molds and urethane resins to produce parts with excellent surface finishes and physical properties.

Injection Molding

When you’re ready for large-scale production, our injection molding services ensure consistent, high-quality parts with efficient turnaround times. We specialize in both prototype and production molds, offering a variety of materials to suit your product’s needs. From small batches to full-scale production, our injection molding capabilities are designed to meet your demands.

When you’re ready for large-scale production, our injection molding services ensure consistent, high-quality parts with efficient turnaround times. We specialize in both prototype and production molds, offering a variety of materials to suit your product’s needs. From small batches to full-scale production, our injection molding capabilities are designed to meet your demands.

We Help You Go From Prototype To Production

Quality Checks at Every Stage for Your Parts

Initial Material Inspection:

Equipment: Optical Emission Spectrometer (OES) or X-ray Fluorescence (XRF) Analyzer. Purpose: Verify the composition and quality of raw materials before production begins.

In-Process Dimensional Inspection:

Equipment: Coordinate Measuring Machine (CMM) and Vernier Calipers. Purpose: Ensure parts meet dimensional specifications during various stages of machining.

Surface Finish Inspection:

Equipment: Surface Roughness Tester. Purpose: Check the surface texture and finish to meet the required standards.

Final Quality Inspection:

Equipment: ZEISS Coordinate Measuring Machine (CMM) and Optical Comparator. Purpose: Conduct a comprehensive inspection of the finished part to verify all dimensions, tolerances, and overall quality.

2 ZEISS CMMs for your project 24/7

We are a 24-hour facility with technicians working 3 shifts. For many of our customer’s urgent projects, we use our 2 ZEISS CMM’s to inspect the parts and make sure your project goes smoothly.

Quality Inspections We Perform for Your Parts

Rapid Printing According To Your Needs

Prototypes: 1-7 Days Lead Time

Small Batches: 7-10 Days Lead Time

Large Volumes: 10-30 Days Lead Time

100% China factory price, no middleman

24 hours factory operation, feel free to contact us

Frequently Ask Questions

The Carbon DLS process is powered by Continuous Liquid Interface Production (CLIP), where ultraviolet light cures liquid resin into solid parts. The light is projected through an oxygen-permeable window, allowing the resin to solidify while the build platform raises the part.

The “dead zone” is a thin layer of uncured resin between the printing part and the oxygen-permeable window. This layer allows the resin to remain liquid while the UV light cures the material above it, enabling continuous production without the need for peeling the part off the window.

Dual-cure materials in the DLS process undergo a second heat-activated chemical reaction after printing. This reaction strengthens the printed part, giving it engineering-grade mechanical properties.

Parts made with Carbon DLS have isotropic mechanical properties, meaning they are consistent and strong in all directions. This is achieved through the dual-cure materials and the unique CLIP process, resulting in parts that are dense and similar to injection-molded components.

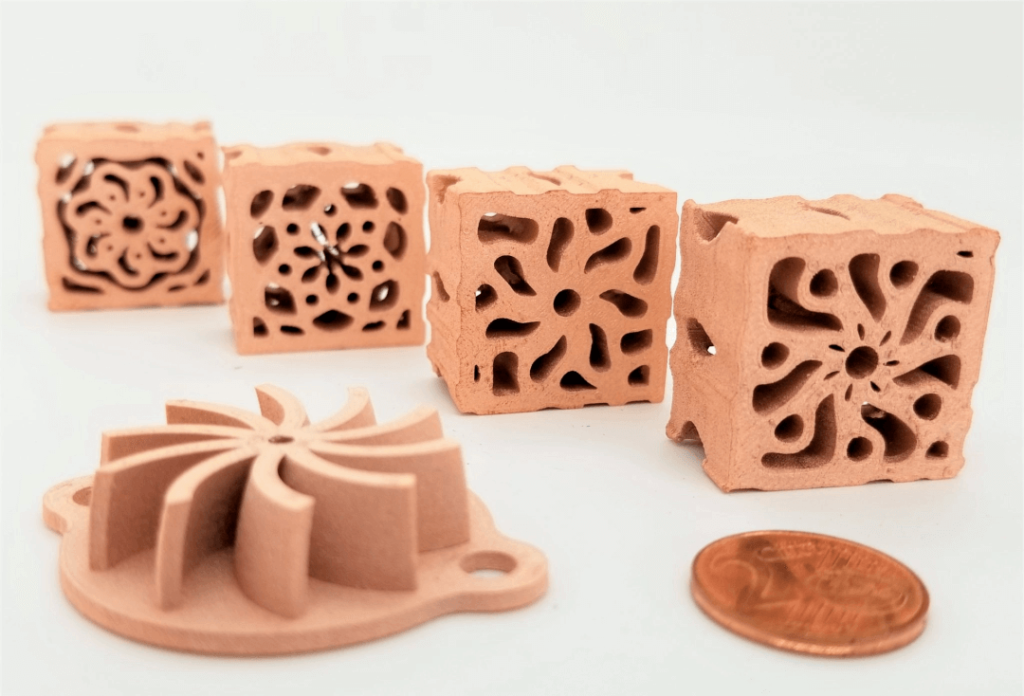

Carbon DLS accelerates product development by allowing rapid design iterations, functional prototyping, and seamless scaling to production. It also provides design freedom, enabling the creation of complex geometries, performance-oriented lattices, and consolidated parts without the limitations of traditional molding.

Yes, Carbon DLS allows for extensive customization without the need for tooling costs. This enables the creation of personalized designs and textures, offering unique aesthetics and surface finishes for each part.

Postprocessing involves cleaning the parts of excess resin, removing any supports, and, for many materials, performing a thermal post-cure in an oven. This heat treatment strengthens the parts by initiating a secondary chemical reaction.

DLS offers parts with surface finishes comparable to injection-molded components, isotropic mechanical properties, and watertightness. It’s ideal for rapid prototyping, bridge production, and creating end-use parts.

DLS has been used in various industries, including for medical devices, dental implements, shoe midsoles, automotive components, food service devices, and aerospace parts.

Bronze 3D Printing Service

Receive quick quotes for parts made from over 70 different metal and plastic materials. All orders comply with ISO 9001:2015, IATF 16949:2016 certifications. Availability may vary, and we cannot always guarantee this service at all times.

Color 3D Printing Service by Modo Rapid

Get instant quotes online for parts made from over 70 metal and plastic materials.

Large Scale 3D Printing Service

Get quotes for large-scale 3D printed parts, available in over 70 different metal and plastic materials.